Error Proofing and Poka Yoke

Prevent Errors in Lean Manufacturing Environments

Error proofing refers to preventing a process from resulting in defects by stopping mistakes at the source, rather than down the line.

Another word for error proofing is poka-yoke (which is Japanese for avoiding inadvertent errors). Poka-yoke design is often used to avoid human error by either warning operators when they are about to make a mistake or preventing them from making a mistake at all. Poka-yoke design makes it virtually impossible for an operator to complete an action incorrectly.

Preventing mistakes at the source can significantly improve productivity by keeping mistakes from becoming bigger problems downstream.

Quality Inspection at the Source

Error-proofing takes quality control to the next level by checking for mistakes and defects before those defects can proceed to the next stage of production. Preventing defects from proceeding from one stage of production to the next avoids wasted time and resources spent working on defective parts.

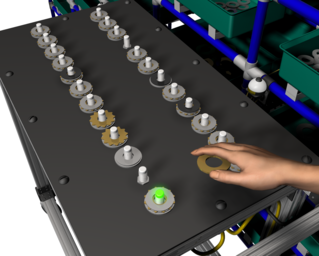

In manual processes, such as bin picking, visual warnings clearly indicate to operators when their actions are correct or incorrect using colored and/or animated lights. Light-guided assembly is an excellent example of using visual indication for error-proofing.

Meanwhile, in more automated processes, error proofing solutions like sensors and vision systems can be used to ensure poblems are corrected before a process can proceed.

Banner Engineering provides sensor, vision, and light-guided solutions for error proofing to help manufacturers increase efficiency, improve quality, and reduce downtime. Keep reading to learn more, or contact us to discuss your specific application.

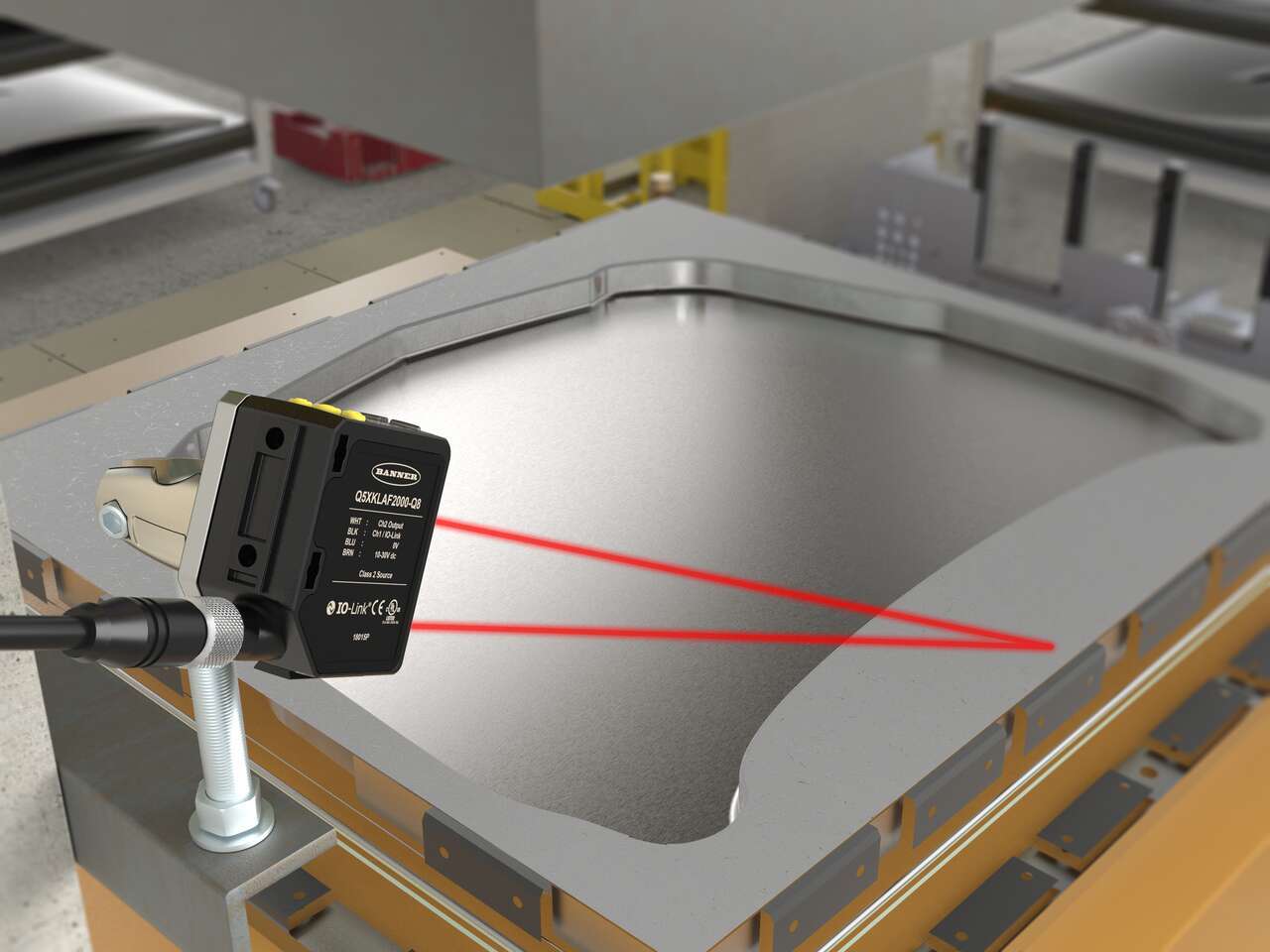

- Laser measurement sensors are often a reliable solution to error-proofing applications.

- Laser sensors from Banner detect and measure the most challenging targets, for error-proofing solutions manufacturers can trust.

- For example, in metal stamping applications, it is critical to ensure that metal sheets are properly indexed on the press before stamping to avoid material waste and damage to the press die.

- The Q5X Series laser sensor reliably detects reflective targets even at an acute angle.

- The press cannot operate until the sensor verifies the leading edge of the material and confirms that the metal sheet is both present and properly indexed.

- In some applications, a vision solution can be an excellent choice for error-proofing.

- For example, in automotive assembly, interior trim pieces are interchangeable, but vary in color, making it easy to install the wrong piece. As assembly progresses, correcting errors becomes more difficult.

- An iVu Color vision sensor verifies that trim colors match the build order for a vehicle.

- If an error is detected (the wrong color trim is placed), the error must be remedied before the automotive assembly can proceed to the next step.

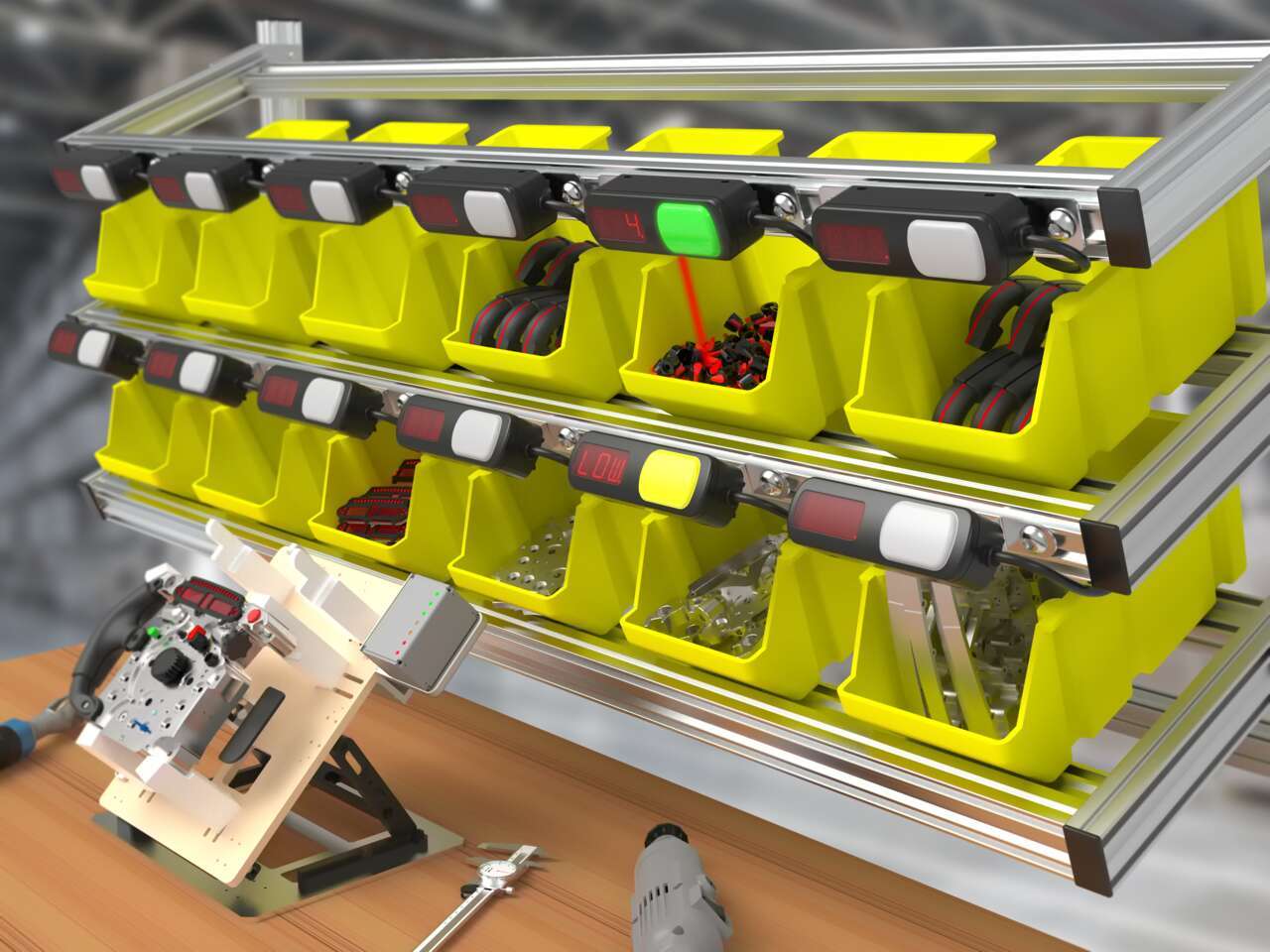

- Perhaps one of the most common error-proofing technologies in assembly processes is light-guided picking, also known as pick-to-light.

- Pick-to-light devices use colored LEDs to visually guide assemblers to pick the correct parts, in the right quantities, and in the proper sequence.

- This reduces the risk of human errors and speeds up build times to ensure high quality while maximizing productivity.

Vision Sensor

iVuまたはiVuカラーイメージセンサは、部品の種類、サイズ、向き、形状、位置、および色または色のバリエーションの監視に使用できます。

- カメラ、コントローラ、レンズ、そして照明が一体になったオールインワンのソリューション

- Vision Manager PCソフトウェア、オンボードのタッチスクリーンディスプレイ、またはリモートタッチスクリーンを使ってわずか数分で構成

- さまざまなグレースケールまたはカラーツールで複数のポイントを検査

- コンパクトで頑丈なIP67ハウジング。統合リングライト付き (赤、青、緑、白、赤外線、UV) または無しで提供

- 適用の柔軟性を最大限に高める、Cマウント付き可換レンズ

- イーサネット/IP™、Modbus/TCP、PROFINET®、PCCC、およびシリアルRS-232

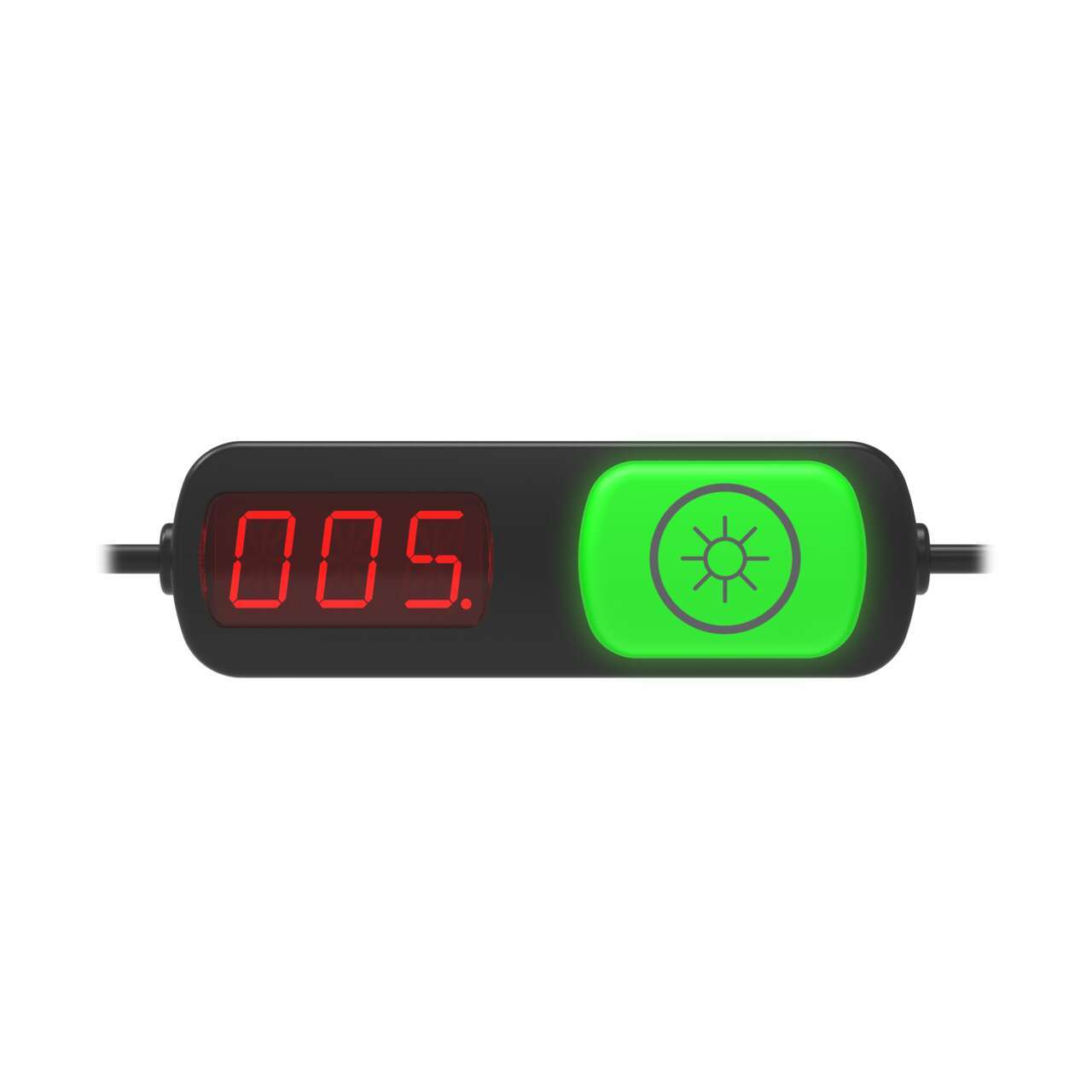

PTL110 Series

Scalable, Versatile Pick-to-Light Devices

PTL110ピックトゥライト装置は、タッチボタン、光学センサ、3桁表示のオプションを備えた多機能インジケータで、連続して接続することにより、強力なピッキングシステムを作り出すことができます。高速応答時間と柔軟な設置オプションを特徴とするPTL110システムは、ピッキング、キッティング、および関連用途における速度、生産性、および品質の改善に役立ちます。

- 光学およびタッチセンサ機能付きのモデルを提供。

- オプションの英数字3桁表示のディスプレイにより、部品カウントやその他の指示を表示可能。

- ケーブルを追加することなく、複数の装置を素早く確実に設置できるM12コネクタ。

- インジケータには14色による多様な照明パターン機能が備わっているため、さまざまな状態を区別可能。

- Common IDを使って複数の装置のポーリングにより発生する一般的な遅延を軽減する特殊なModbus互換シリアルバスプロトコル PICK-IQ™ を使用。

- DXM700ワイヤレスコントローラとペアリングすることで、カートや可動式ピッキングステーションでの実装が可能。