Detecting Dark Objects

Dark objects, such as solar wafers or automotive parts, absorb a large amount of light, especially red light. Due to the low reflectivity of these targets, it can be challenging for LED- and laser-based sensors to reliably detect the presence of very dark objects—especially against a similarly dark background.

In spite of the challenges, there are both photoelectric and laser sensors that can reliably solve these applications. Keep reading to learn how to identify a solution for dark object detection.

There are several options for detecting dark objects. A through-beam or retro-reflective photoelectric sensor is an obvious choice since the sensor can easily detect when a dark object passes between the emitter and reciever unit, or when the beam of light between the emitter and a reflector is interrupted. However, in many applications, mounting devices on both sides of the application is impractical, if not impossible.

In these cases, a diffuse sensor (emitter and receiver in the same housing) is required. However, diffuse sensors rely on the target to act as a reflector, and targets must return enough light back to the sensor to verify the object's presence. If a target aborbs the majority of the light, as in the case of dark objects, the sensor may fail to reliably detect the target. To solve these challenges, a sensor with high excess gain, or blue light instead of red, can help ensure reliable detection.

In many of these applications, not only must the sensor detect the dark object, but it must do so against an equally dark background (for example, detecting dark parts on a dark auto body panel). The lack of contrast between target and background is also challenging for many photoelectric sensors to detect. For these applications, a distance-based laser sensor is a must. Keep reading to learn why.

Excess gain is an important metric for any application, but it is especially important when detecting dark objects. Excess gain is a measure of the minumum light energy needed for reliable sensor operation. A high excess gain helps the sensor overcome a weaker signal reflected by a dark object.

The amount of excess gain you need, over and above what you might need for a "typical" target, will depend on how dark your target is as well as the environment of your application. Pristine environments with little dust will require less excess gain than a dirty environment with debris that can cloud the sensor lens and further reduce signal strength.

Fortunately, determining the amount of gain you need doesn't have to be a manual process. Smart sensors can recognize if very little light is returning to the receiver and automatically adjust exposure settings for additional gain and a stronger signal.

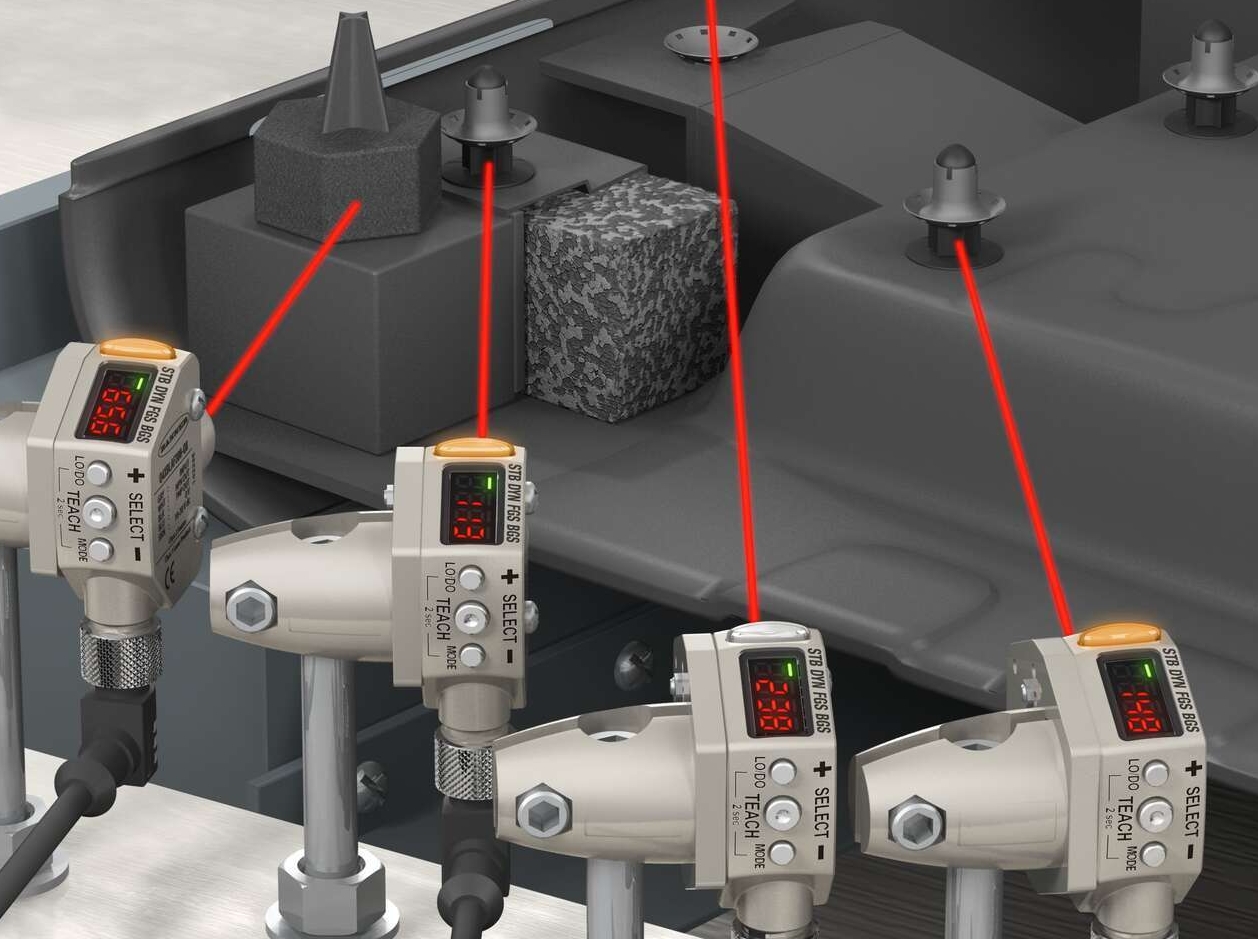

Sensors that rely solely on contrast will struggle to detect very dark objects against a similarly dark background; however, these applications are common, especially in the automotive industry. For example, in the application pictured to the right, verifying that foam and other components are present on automotive door panels is extremely important. If any part is missing, the quality of the final door assembly is adversely affected.

Since door panels are often dark colors such as black or gray, and the foam used to eliminate rattles and provide stiffness is generally black, it can be difficult for standard sensors to differentiate between foam presence and absence due to poor contrast. A laser measurement sensor can reliably detect these parts by detecting changes in distance instead of color.

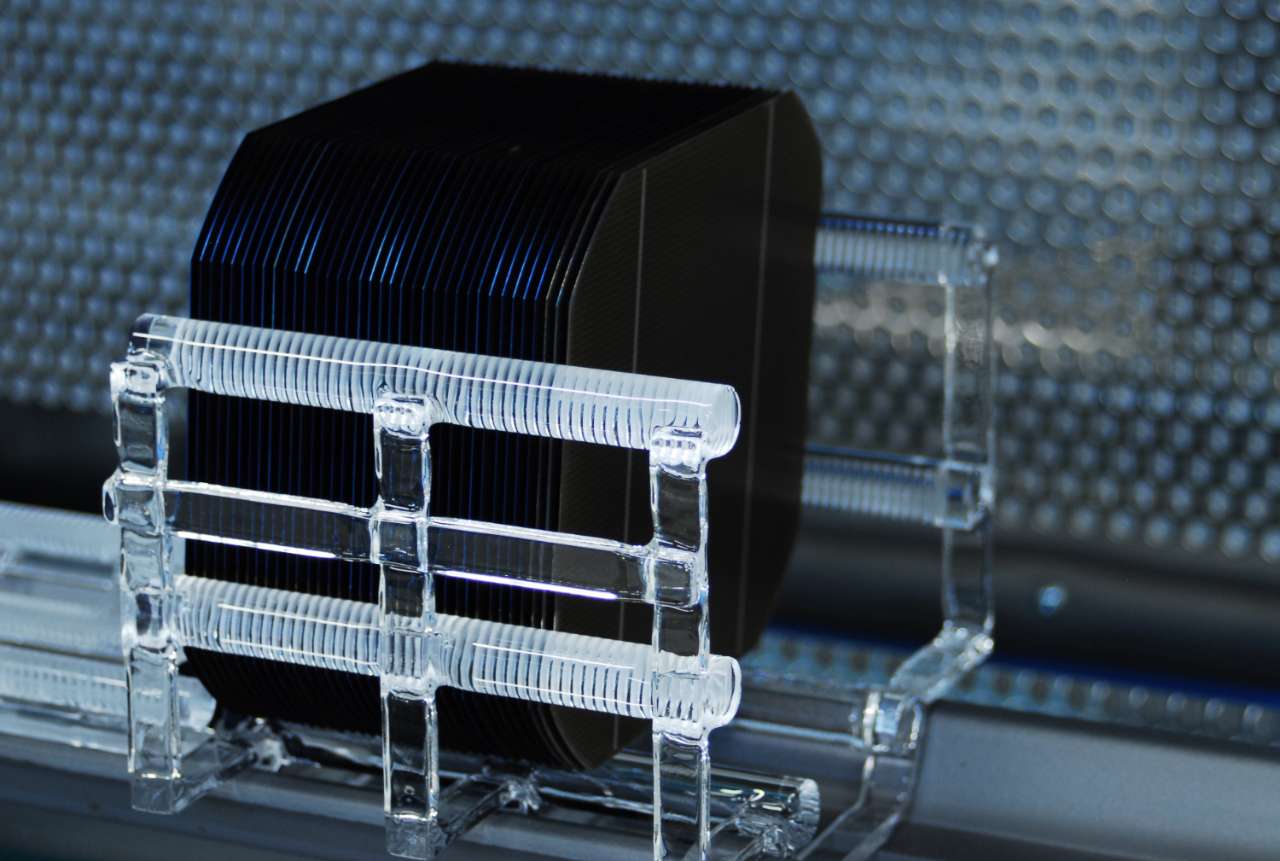

Some targets are designed specifically to absorb red light. For example, solar wafers are designed to absorb as much sunlight as possible and are covered in anti-reflective coating. This makes solar wafers very difficult for traditional photoelectric sensors to detect.

In these applications, a photoelectric sensor with a blue LED light can be a cost-effective solution. Blue light is not absorbed by dark objects to the same extent as red light. Since more light is remitted back to the sensor, a sensor with blue light will be able to detect extremely dark objects with greater reliability.

Laser Distance Sensor, 9.5 cm - 2 m Range

Q5X背景抑制レーザーは、業界標準の長方形ハウジングを備えたコスト効率の良い強力なセンサで、あらゆる問題を解決します。

- レンジ 9.5 cm (4インチ)~2 m (6フィート6インチ)

- 類まれの高過剰ゲインにより、遮光性の非常に高い物体 (<_6 の反射性遮光ターゲット="の反射性遮光ターゲット" でも確実に検出="でも確実に検出" li="li">

- 遮光背景の遮光ターゲット、光沢性の金属背景の遮光ターゲット、透明体、反射体、多色包装、およびあらゆる色のターゲットを確実に検出

- 距離と光の明暗度の両方を測定するデュアルティーチモードにより、非常に困難な用途でも解決可能

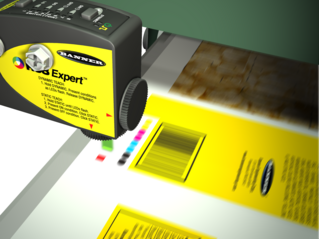

Photoelectric Sensor with Blue LED

- ごくわずかなスペースに設置できる小型センサ

- 小さな部品の検出を最適に行える、明るく正確なレーザースポットを提供する赤レーザーモデル

- 遮光性や反射性のある物体や透明体などの困難なターゲットを、反射板を使用せずに確実に検出する青LEDモデル

- 最も高速なプロセスでも検出できる高いスイッチング周波数

- 電子押しボタンまたはリモート入力を使った操作性で確実かつ正確に検出

- 用途に合わせて検出ビームを選べる、赤レーザー、赤LED、および青LEDモデル

- 堅牢なガラス繊維強化プラスチック製ハウジング

- PNPまたはNPN出力 (一部モデル)