Improving Productivity and Quality with Pick-to-Light Products

eFlex Systems, an Epicor solution, empowers manufacturers by offering a turn-key platform to improve productivity and reduce errors in a wide variety of assembly processes. Their Manufacturing Integrated Platform (MIP) helps guide assemblers, reduce learning curves, and close the data gap between the production floor and ERP systems. Their solutions are deployed in markets including automotive, appliances, medical devices, and more.

The relationship between eFlex and Banner started many years ago and remains strong to this day. eFlex had originally used Banner’s K50 capacitive touch buttons for picking/kitting applications in the automotive industry. When Banner’s PTL110 pick-to-light product was launched, eFlex became an early adopter due to several new features, such as the device’s indicator for quantity and the ability to differentiate between multiple touches, that would deliver even more value and convenience to their platform and customers.

One example of how eFlex deployed the PTL110 was at a hydraulic pump manufacturer who was trying to error-proof and reduce cycle times in one of their assembly processes. The customer had a kitting cell for building hydraulic pumps. Each of the pumps that they build are made to order; the bill of materials could include any combination of valves, fittings, orifices, or seals. The manufacturer had been documenting rework problems they were having due to the wrong components being used in the pump assembly. Knowing there had to be a way to improve their process, the manufacturer decided it was time to implement a picking system with advanced functionality to meet their needs.

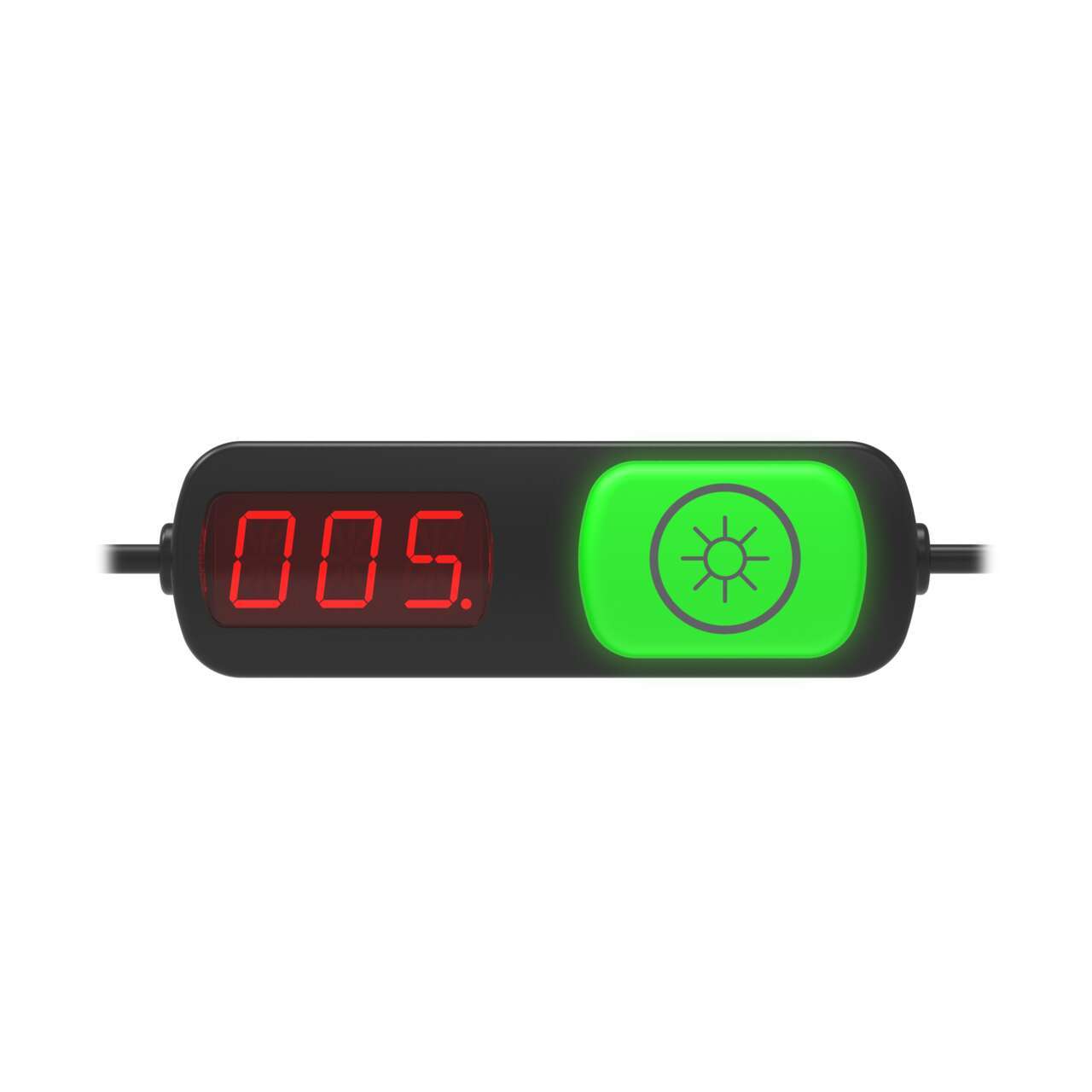

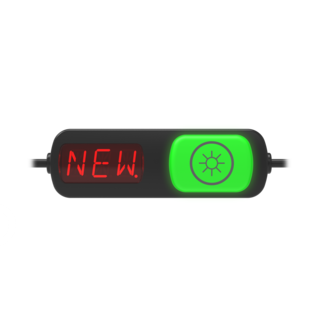

The first implementation of eFlex’s system at this customer included (50) PTL110 pick-to-light buttons to help assemblers pick the right parts when building the pumps. Installing the system was simplified due to the ease of connectivity with eFlex’s plug-and-play hardware capabilities and the fact that the PTL110 can be connected in a series instead of using point-to-point wiring. Further assisting installation was the PTL110’s serial communication protocol, eliminating the need for I/O to control the lights, reducing system complexity. Assemblers benefited from the bright, multicolor LED indicators guiding them to pick the right component every time. The PTL110’s multi-segment display provides easy-to-read pick quantities when more than one part is needed per bin. Lastly, assemblers can move quickly through the picking process by either pressing the standard touch button to acknowledge the pick, or by using the optional optical sensor to detect that their hand was in the bin.

Once installed and commissioned, the MIP system allowed for quick setup of the various pick sequences based on the pump’s bill of materials. The hydraulic pump manufacturer realized immediate return on investment, with the initial system saving them hours of time and reducing defects, helping them achieve their original goals. MIP provided real-time data on the assembly process that showed how the PTL110s enabled faster, more accurate picks.

Fast, Scalable Solution to Maximize Productivity

PTL110 pick-to-light devices are powered by PICK-IQ™, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that results from polling multiple devices. The fast response speed at scale makes PTL110 an ideal solution for production lines and fulfillment stations that require many pick points, while maintaining a rapid pace to exceed productivity targets.

Solve more Applications with Flexible Pick Functionality

PTL110 models are available with optical sensor and touch button capabilities for versatility in solving diverse pick-to-light, put-to-light, and kitting applications. These functions can be used individually or together to confirm standard pick actions plus secondary functions. The optional display can be used to indicate part count or provide other instructions with alphanumeric characters. Users have full control of fourteen colors and multiple animation functions to clearly differentiate multiple conditions.

Reduce Costs with Simple Mounting and Installation

Each PTL110 device has two M12 connectors for quick and secure installation of multiple devices with no additional cables required. Connect device-to-device or add standard patch cables to fulfill your application requirements. PTL110 devices can be fastened to tubes, extrusion, and rail with a variety of brackets or standard cable ties. They can be quickly moved and replaced with no tools, rewiring or reprogramming required.