DXM1200 IIoT Gateway Series

Banner’s DXM1200 IIoT Gateway wireless controllers collect and process condition monitoring data from nearly anywhere, then sends anywhere in the world.

A car wash depends on multiple systems working in tandem. Failure in any piece of equipment could cause an unexpected shutdown, resulting in lost revenue and unplanned maintenance.

But Banner Engineering can help you detect equipment breakdowns before they happen.

Maximize vehicle throughput and reduce unexpected downtime with Banner Engineering’s Predictive Maintenance Solutions for Car Washes.

To monitor equipment in the back room, use Banner’s Q45 All-In-One Series sensors, starting with an ultrasonic model that accurately measures the water level in the storage tanks. The vibration and temperature of the delivery pump’s motor gets monitored with another peel-and-stick Q45, and an additional Q45 monitors the water pressure on the main water line.

Further down the line, monitor the vibration and temp of all the different distribution pump’s motors, such as at the detergent pump station, sealer stations, and the high-pressure water pump stations.

Additionally, monitor the reclaim storage tanks for low water levels, which may indicate the RO’s filter needs cleaning. The reclaim delivery pump’s motor is also outfitted with a temp and vibration sensor to alert users to mechanical maintenance needs.

But monitoring solutions don’t have to stop at the water system; nearly any equipment can be monitored, such as the pneumatic air system. Temperature and vibration sensors monitor the air compressor motors alongside a current sensor for consistent power usage, as well as a pressure sensor on the primary air line.

Outside, monitor the central vacuum’s motor with a temp and vibration sensor. The filter’s efficiency can be calculated by comparing the air pressure both upstream and downstream of the separator, indicating when the filter needs cleaning.

All the data from each of these sensors is transmitted wirelessly to a DXM controller mounted in a safe and convenient location. Sensor calculations are performed inside the controller, and data can be transmitted to wherever you need it via Ethernet cable or a cellular connection. Additionally, alerts can be sent to workers via email or text message, so mechanical problems can be addressed quickly.

But, passive monitoring doesn’t have to stop there.

Back in the tunnel, use a temperature and vibration sensor to track the machine health and performance of the conveyor’s motor and gear box. Additionally, consider using a Q45 to track vibration on the air blowers.

Next, add a T30RW radar sensor to the tunnel entrance and exit to reliably detect when vehicles arrive and leave.

Further inside the tunnel, accurately detect vehicles at specific locations, such as an applicator arch, with the QS30 Photoelectric Sensor.

And speaking of applicator arches, Banner's extensive line of customizable RGB lights, many of which are programmable and animated, will add an exciting splash of color and movement while also indicating different wash levels, customer-selected sealers, progress indication, and more.

The only limit to indicator integration is your imagination.

To learn more, visit BannerEngineering.com/carwash

Banner’s DXM1200 IIoT Gateway wireless controllers collect and process condition monitoring data from nearly anywhere, then sends anywhere in the world.

50 mmドームまたはフラットウィンドウ搭載のプログラム可能な汎用インジケータは、より明確で明るくステータスを表示します。Pro Editorソフトウェア対応またはIO-Link通信機能付きのいずれかのモデルを用意し、多用途性やカスタマイズ性を追加しています。

K70表示灯は、1台のライトで最大5色に対応した大型の70 mm表示灯です。広範な用途に使用できる頑丈で明るいカラー表示灯です。

Q45 Series all-in-one devices combine a wireless node, sensor, and battery power supply in one easy-to-deploy device that monitors assets and equipment in remote and hard-to-access locations.

QM30VT Series vibration and temperature sensors offer exceptional levels of accuracy to detect even slight changes in machine health and performance, enabling early identification of potential problems.

検出距離最大200メートルの高性能センサ。E/Mリレー出力モデルを用意。

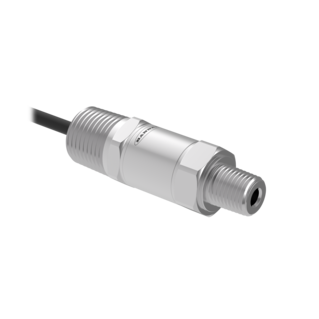

The Performance Series all-in-one pressure sensor and wireless node makes it easy to monitor pressure levels on systems and equipment in remote and hard-to-access locations without wired infrastructure to connect devices.

T30R センサは、超音波センサに代わるさらにロングレンジのセンサであり、極端な屋外条件やその他の困難な環境において、より信頼性の高い検出と位置フィードバックを提供します。従来の 24GHz レーダーセンサよりもデッドゾーンが短く、精度が高く、広範囲のターゲットを確認することができるのが特徴です。

この明るい大型のタワーライトは、組み立て済みの製品として、またはカスタマイズ用モジュラー式セグメントとして購入できます。消灯時はグレーになるため、誤表示を防止できます。

Banner is expanding its offering of the WLS27 Series Strip Light to include programmable models with RGBW LEDs for use in indication, illumination and inspection applications. These new models will be programmable with Banner’s Pro Editor software or IO-Link communication.

多様な産業用途に適した21 mmの薄型でコンパクトなLEDライト。モーションセンサ付きモデル、各種レンズ および窓の選択が可能で、最大限の柔軟性を実現。

Sure Cross® 温度湿度センサは、多様な環境で機能し、温度と湿度を測定します。Sure Crossワイヤレス無線と組み合わせると、監視ポイントまでコストのかかる配線作業を行わず、環境条件を簡単に監視することができます。

Application solutions, new product updates, answers to frequently asked questions, and more delivered 1-2 times a month.