Indication for Picking Order

Challenge: Manual Bin Picking Reduces Efficiency

The implementation of efficient processes is crucial in assembly workstations to maintain productivity and reduce downtime. In a recent pick-to-light application, the facility manager wanted to upgrade their existing assembly workstation to improve assembly guidance. Pickers were frequently picking from the wrong bins. This would often result in time spent trying to determine which bin they were supposed to pick from. An automated, intuitive solution was needed to guide the pickers to the correct bin.

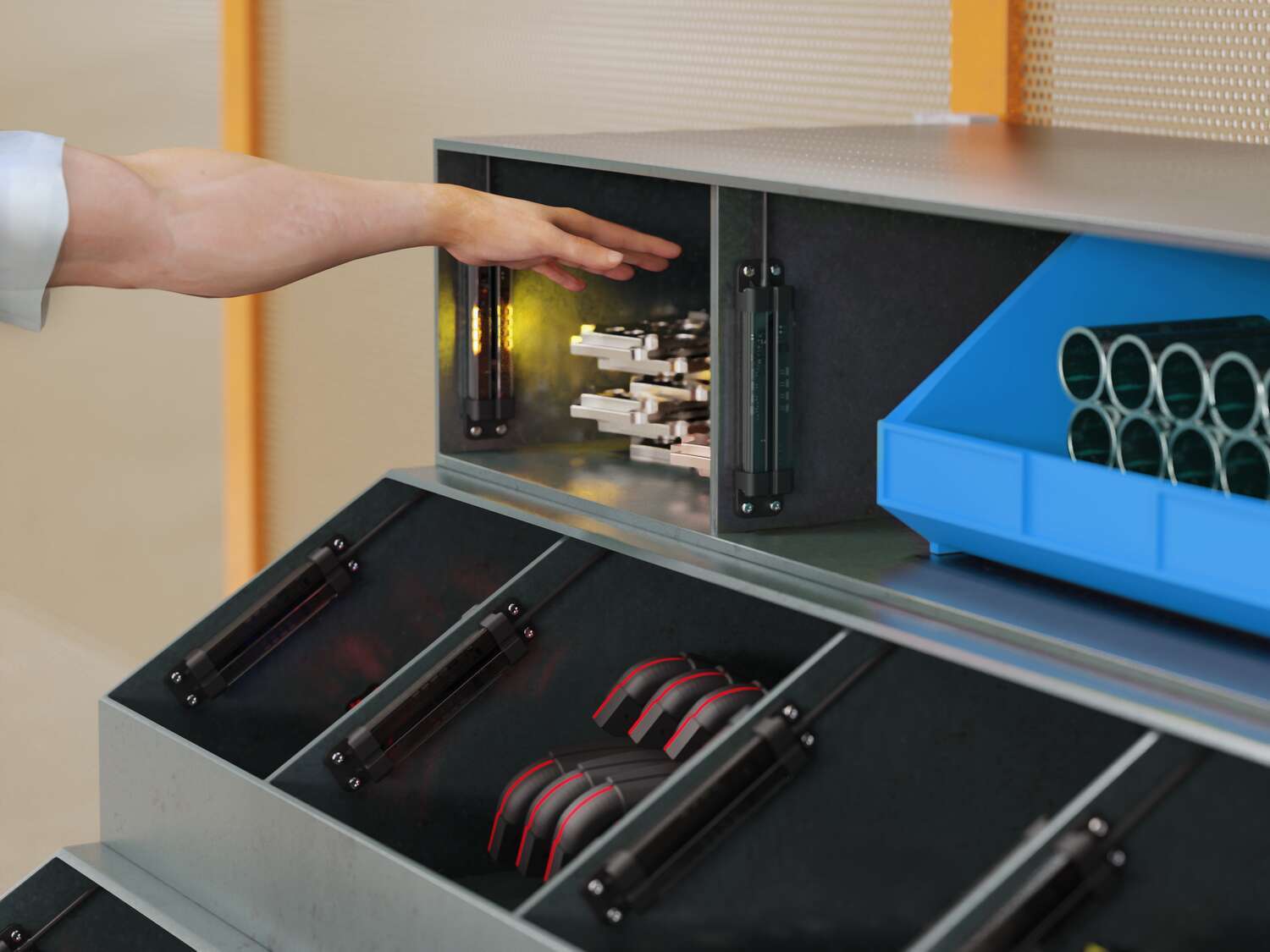

Solution: PVS28 Provides Multicolor Assembly Guidance

PVS28 Parts Verification Sensors were installed alongside each bin at an assembly workstation. The PVS28 was programmed to turn colors based on where in the picking sequence the picker was at. For example, when the device was green, it meant that the picker pick from that corresponding bin. Yellow gave an acknowledgement of correct pick. When it was red, it served as an immediate notification to workers that they had made a mistake. The PVS28 served as an immediate resource to workers for identifying which bin they should select from and when they made an error. It guided them with distinct indication throughout the entire picking process. This reduced onboarding time for new workers and minimized rework and scrap expenses caused by incorrect assembly. If the pickers wanted a wider selection of colors or wanted to add animations as part of their process, they were able to do so with Pro Editor software.