レジストレーションマークの検出:RGB技術を備えたカラーマークセンサを採用する理由

まとめ

レジマークは包装材を識別するためもので位置制御に使用され、包装材のウェブの分離や切断箇所を示す働きをします。ウェブは高速で処理され、製品の変更も頻繁になることがあります。レジストレーションマークのサイズや場所、材料の色、光沢、半透明性は、マークの検出精度を大きく左右することがあります。 RGB技術を備えたカラーマークセンサがどのようにレジストレーションマークを検出するのか、どのようなときにトゥルーカラーセンサではなくカラーマークセンサを使用するべきかなど、以下で詳しくご紹介します。

質問:トゥルーカラーセンサとカラーレジマークセンサの違いは何ですか?

トゥルーカラーセンサはわずかな色の違い(例えば紺色と黒)を検出するように調整できますが、カラーマークセンサでは色調の変化が検出されます。 バナー製QC50のようなトゥルーカラーセンサでは、白色LEDと赤、緑、青のフィルタエレメントを用いてターゲットに光を照射します。そして、ターゲットに反射した光の量に基づいて、センサに戻ってきた光に色値が割り当てられます。カラーマークセンサではLEDのみを使用し、フィルタはありません。背景色とのコントラストによってターゲットの色が識別されます。

質問:カラーマークセンサより、トゥルーカラーセンサを使う方がいいのではないですか?

そうとは限りません。色識別の多くの用途で、カラーマークの色調の変化を検出することで大きな効果を期待できることが分かっています。特にハイスピード処理が求められる用途では、R58Eのようなカラーマークセンサを使用することをお勧めしています。トゥルーカラーセンサが必要になるのは、例えば水色と紺色の識別が必要な場合など、色のみが異なるターゲットを選別する場合です。その一方で、変化のない背景にあるレジマークを識別するのであれば、カラーマークセンサが妥当であると言えます。

質問:トゥルーカラーセンサとカラーレジマークセンサの違いは何ですか?

それは同じセンサのことで、違いはありません。

質問:センサの仕様にある、16階調のグレースケールとは何を意味しますか?

カラーマークセンサの特徴を表す方法のひとつとして、センサが検出できるグレースケールの階調の数を使用します。センサの分解能が小さいほど、より多くの階調を検出することができます。市販のプリンタのグレースケールチャートは黒から白まで20の段があり、その間にさまざまな濃淡の灰色が配列されています。だいたいのセンサは白から16段を検出できます。

質問:バナーのR58Eはグレースケールの階調に対応していますか?

R58Eは16階調のグレースケールに必要な仕様を余裕をもって満たしています。RGB LEDを持つR58Eの分解能は、グレースケールチャートを大幅に上回ります。R58Eでは微妙なコントラストの変化も識別することができ、16階調のグレースケールを超える性能を持っています。

質問:カラーマークセンサの処理時間がスピードに影響するというのは本当ですか?

スピードが問題になるのはカラーマークセンサよりトゥルーカラーセンサの方でしょう。バナーのR58では1秒間に10.000回の検出が可能で、これは非常に速いスピードであると言えます。

質問:バナーのR58Eカラーマークセンサにはどうして赤緑青のLEDがあるのですか?

R58Eではこのような色の組み合わせによって、事実上すべてのレジマークと背景の組み合わせを確実に検出できるようになっています。RGB (赤、緑、青) の色を組み合わせることで、ほぼどんな色でも表現できます。例えばモニタでも、RGB技術によって何百万という色の表示が可能です。R58Eではこの3つの色を使って、レジマークの色と背景の色を判断します。そして、レジマークと背景の最良のコントラストを得るためにLEDが使用されます。

質問:用途に合ったLEDの色をどのようにして選択すればいいですか?

R58EではLEDの色を選択する必要はありません。最初のティーチ機能の実行中に、適切なLEDの色が自動的に選択されます。ただ、モノクロカラーマークセンサを使用する場合は、色選択チャートなどを使って適切なLEDの色を選択します。

質問:LEDの色はどのように切り替えるのですか?

手動でLEDを切り替える必要はありません。ティーチ機能の実行中に、適切なLEDの色がR58Eによって自動的に選択されます。

質問:R58EのLEDの色を選択することはできますか?

できません。R58Eには赤緑青の3色のLEDのみを使用できます。

質問:LEDの色が3つあることで、センサの応答時間に影響はありませんか?

ありません。最初のティーチプロセスの後、R58Eの応答時間は同等のレジマークセンサと変わりません。R58Eの応答時間は50マイクロ秒で、15マイクロ秒の反復性となります。

質問:透明な材料にあるレジマークはどのように検出するのですか?

透明な材料(透明なポリ袋など)は光をあまり反射しないため、センサに反射光が戻って来るように、透明な材料のすぐ後ろに反射面を配置してください。レジマークがある場所は光がさえぎられて反射面まで到達せず、レジマークがセンサに検出されます。透明な材料から光が入らないようにするため、センサを15°の角度に傾けて取り付けることをお考えください。

質問:高感度が必要な用途で、R58Eを使ってどのように検出精度を最大まで高めることができますか?

動的ティーチ機能を使って、検出しながら一連の検出条件をティーチングしてください。R58Eで背景に対して複数のレジマークがサンプリングされ、自動的に感度が最適なレベルに設定されます。

関連記事

-

IP等級とNEMA等級を正しく理解して適切なセンサを選定する方法

-

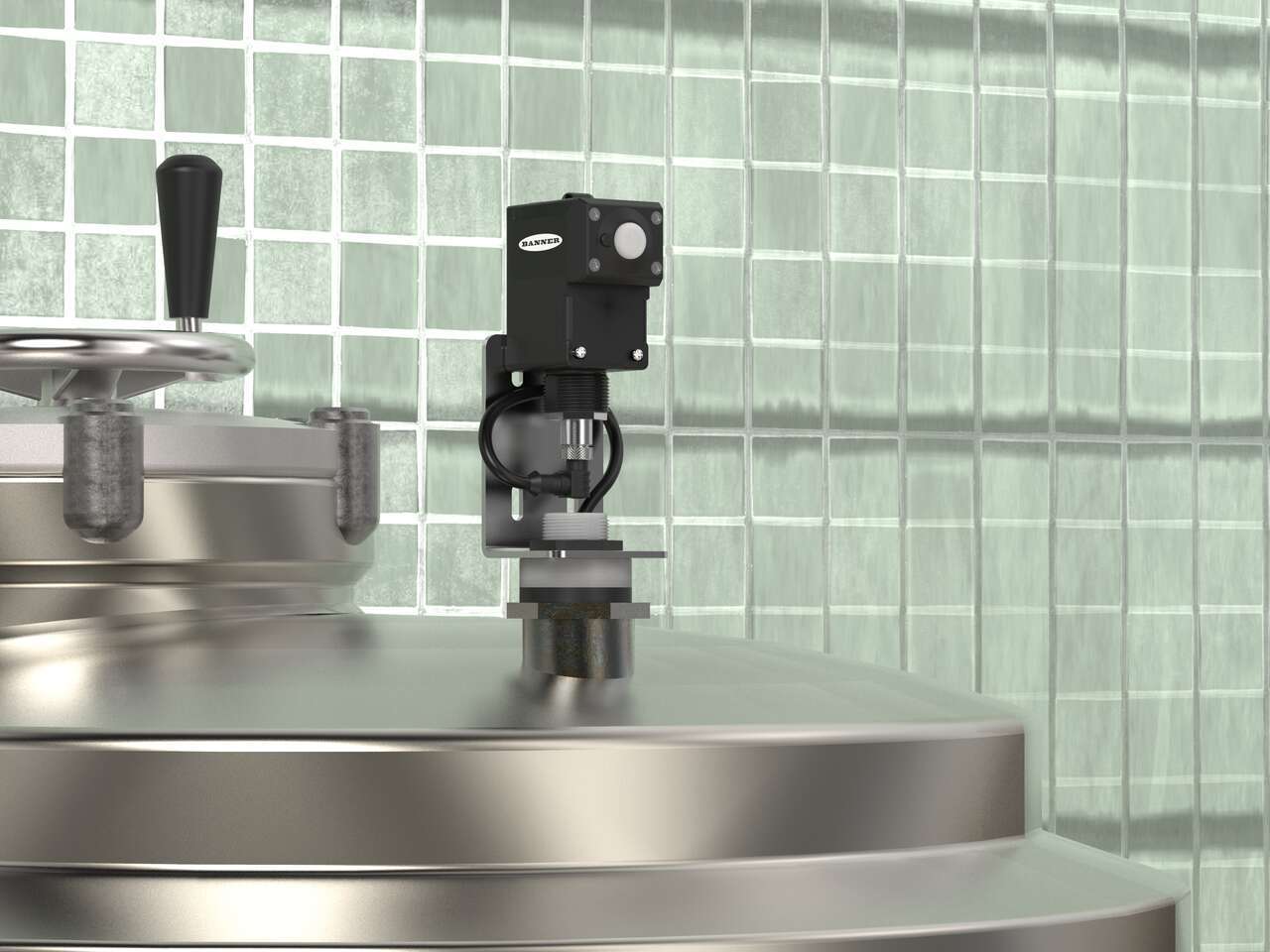

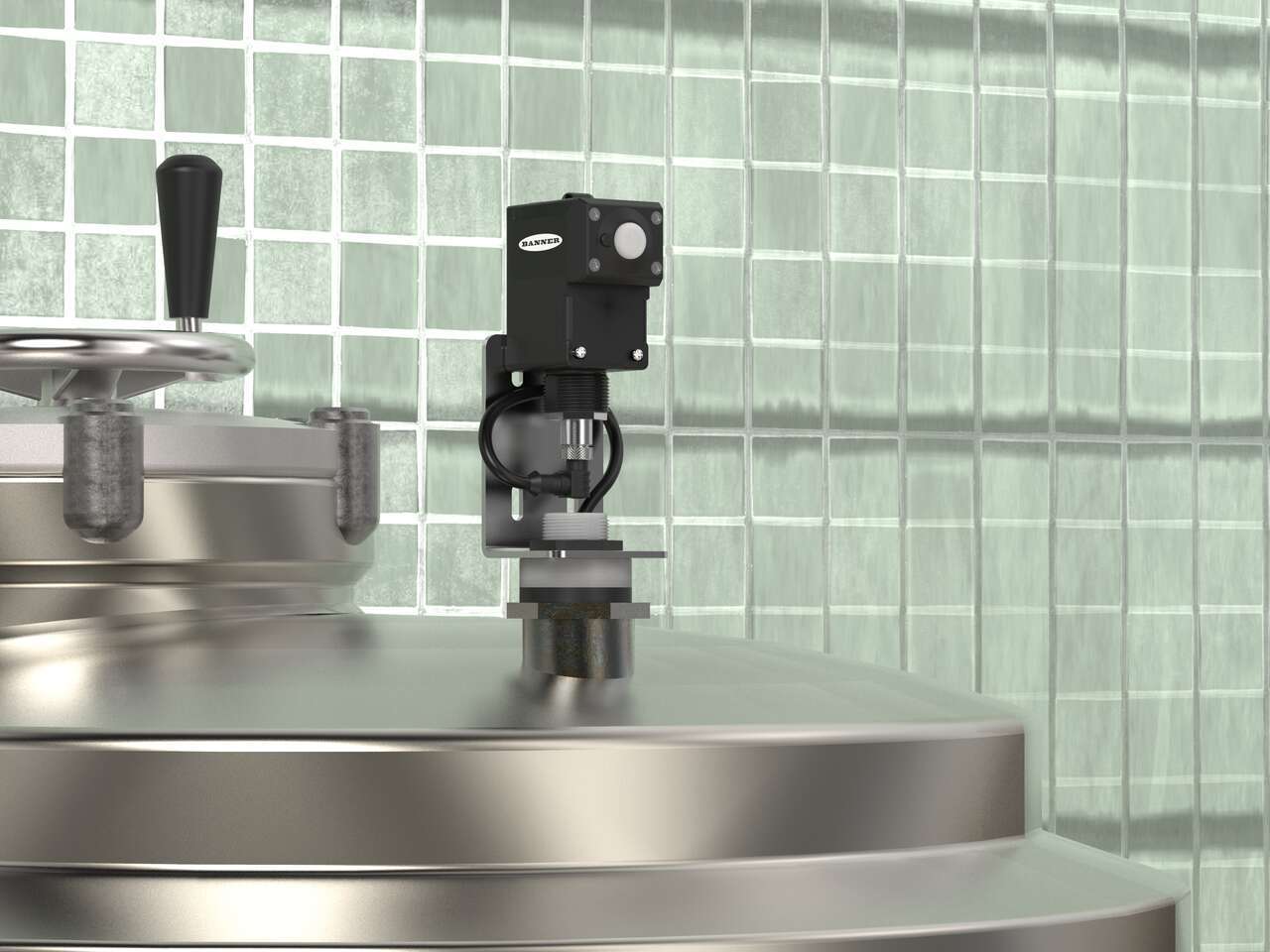

タンクレベル監視:ワイヤレスソリューションの3つのメリット

-

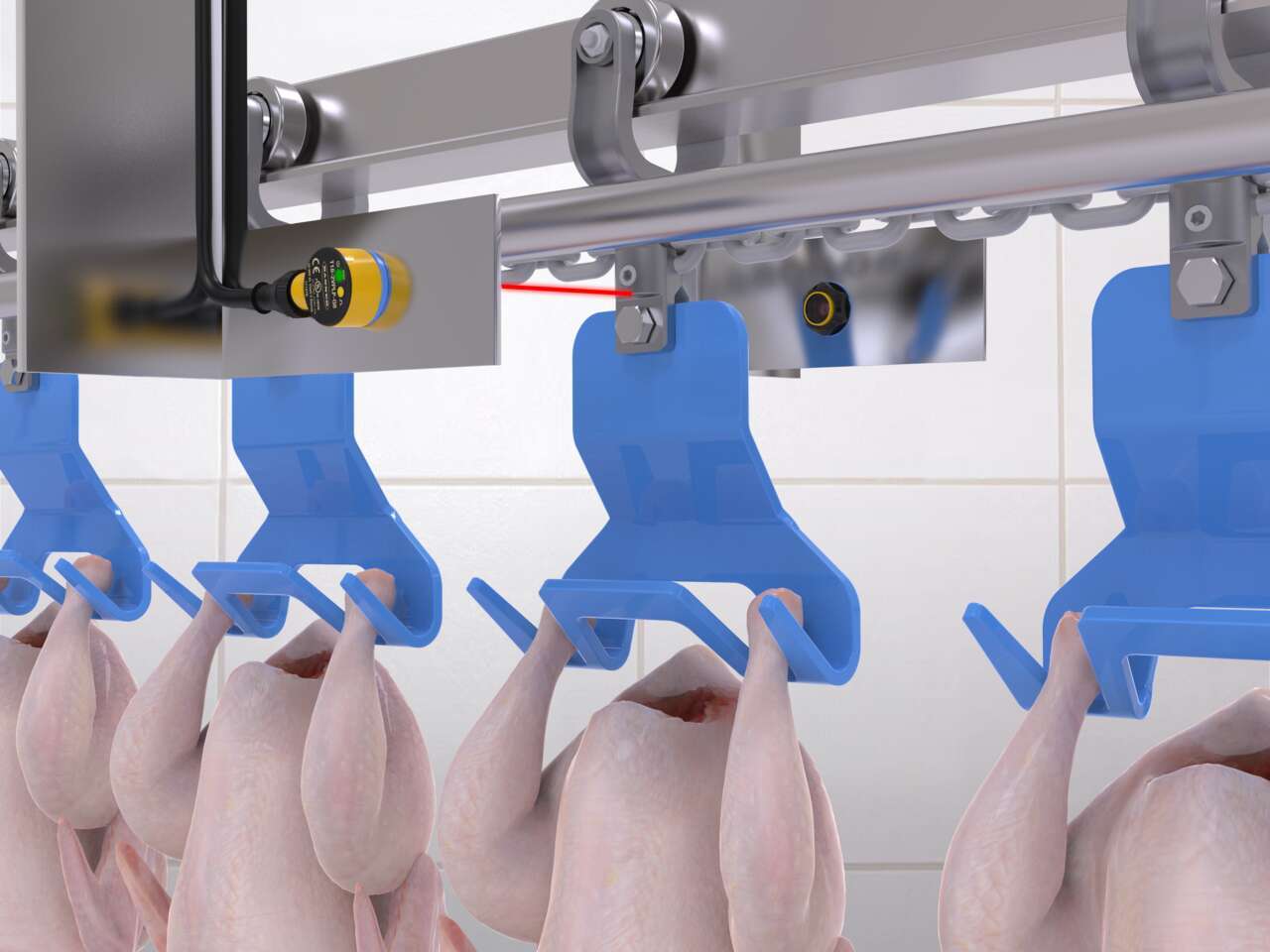

食の安全に対する3つの危険要因とセンサソリューションの選定方法

-

タンクレベル監視:ワイヤレスソリューションのメリット

-

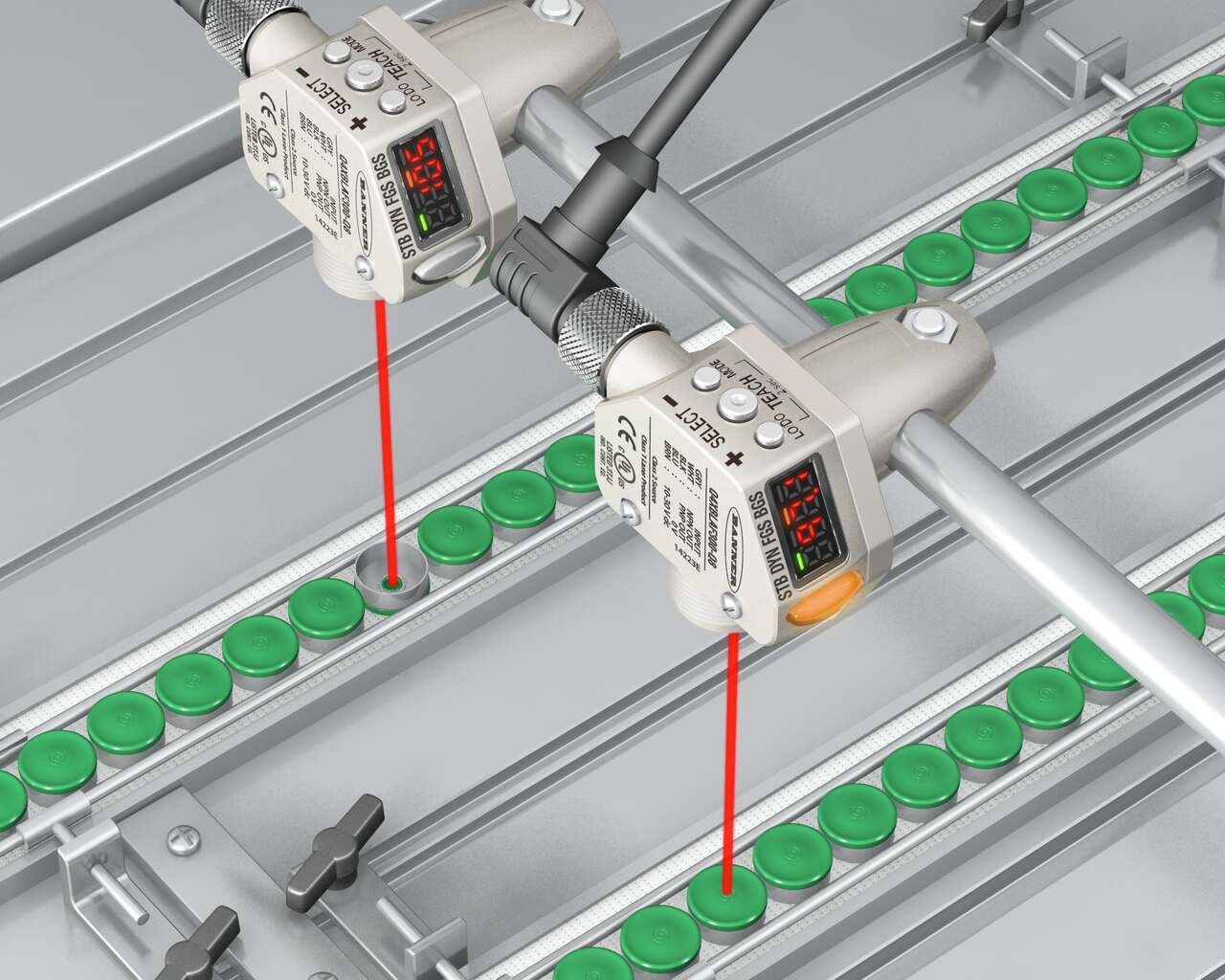

レーザー計測センサーの仕様を解説

-

リモート監視による機械整備の改善

-

3 光電センシングモードとその選び方

-

過剰ゲインとは?センサの選定基準として使用する方法

-

2017年、産業オートメーションで最もホットな5つのトレンド

-

スマートセンサ: リモート監視とOEEのためのIO-Link

-

プラスチック製、それともガラス製の光ファイバ? 選定方法

-

赤外線光電センサーによる車両検知

-

光ファイバセンシング技術:その概要と仕組み

-

光電センシングに光ファイバを使用する理由

-

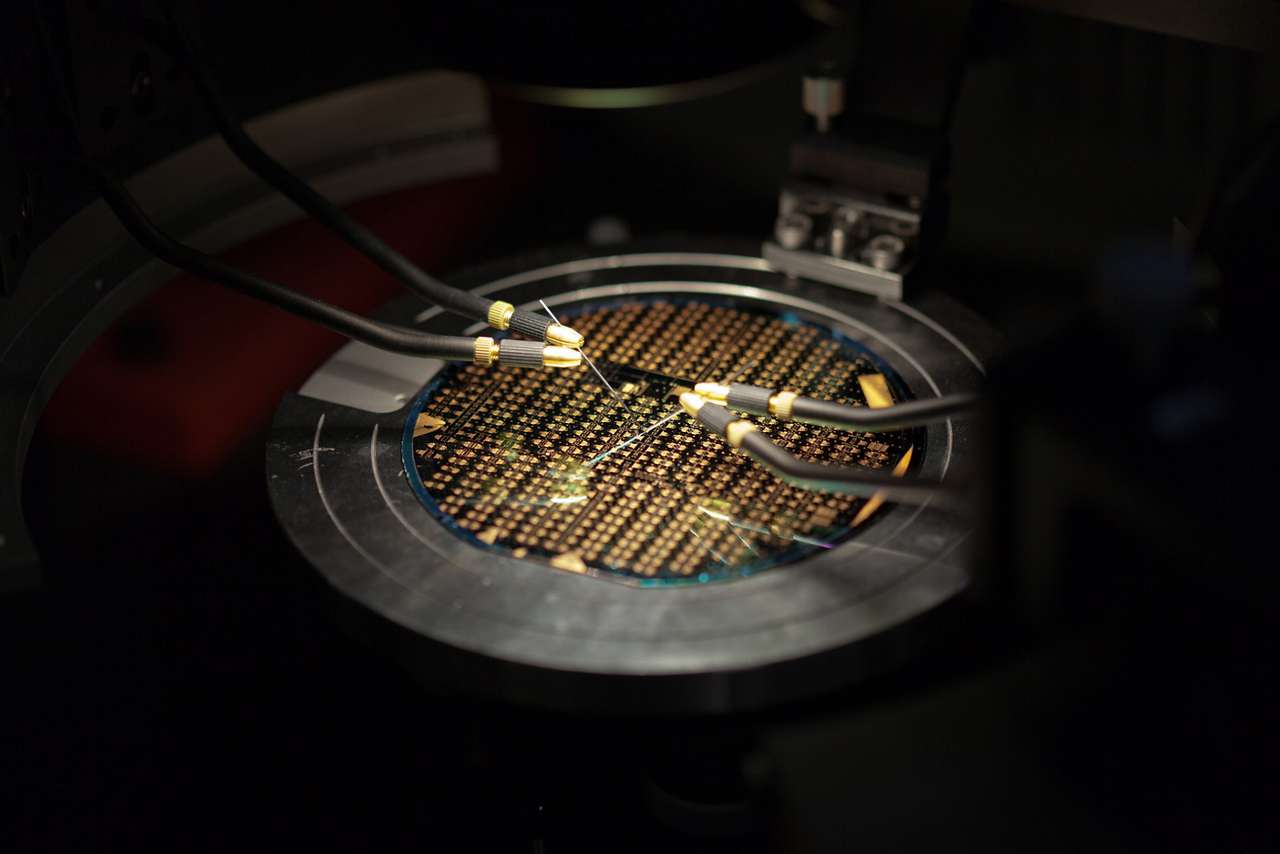

半導体ウェハー存在検出の3つのソリューション

-

赤外線光電センサを水ベースの液体の検出に使用する方法

-

ルミネセンスセンサ:よくある質問とその回答

-

透明体検出に最適なセンサの選定方法