Banner Engineering Cascading Safety Light Curtains

Learn how Banner Engineering's light curtains' cascade signals outpace the competition, and how that translates to savings in the factory.

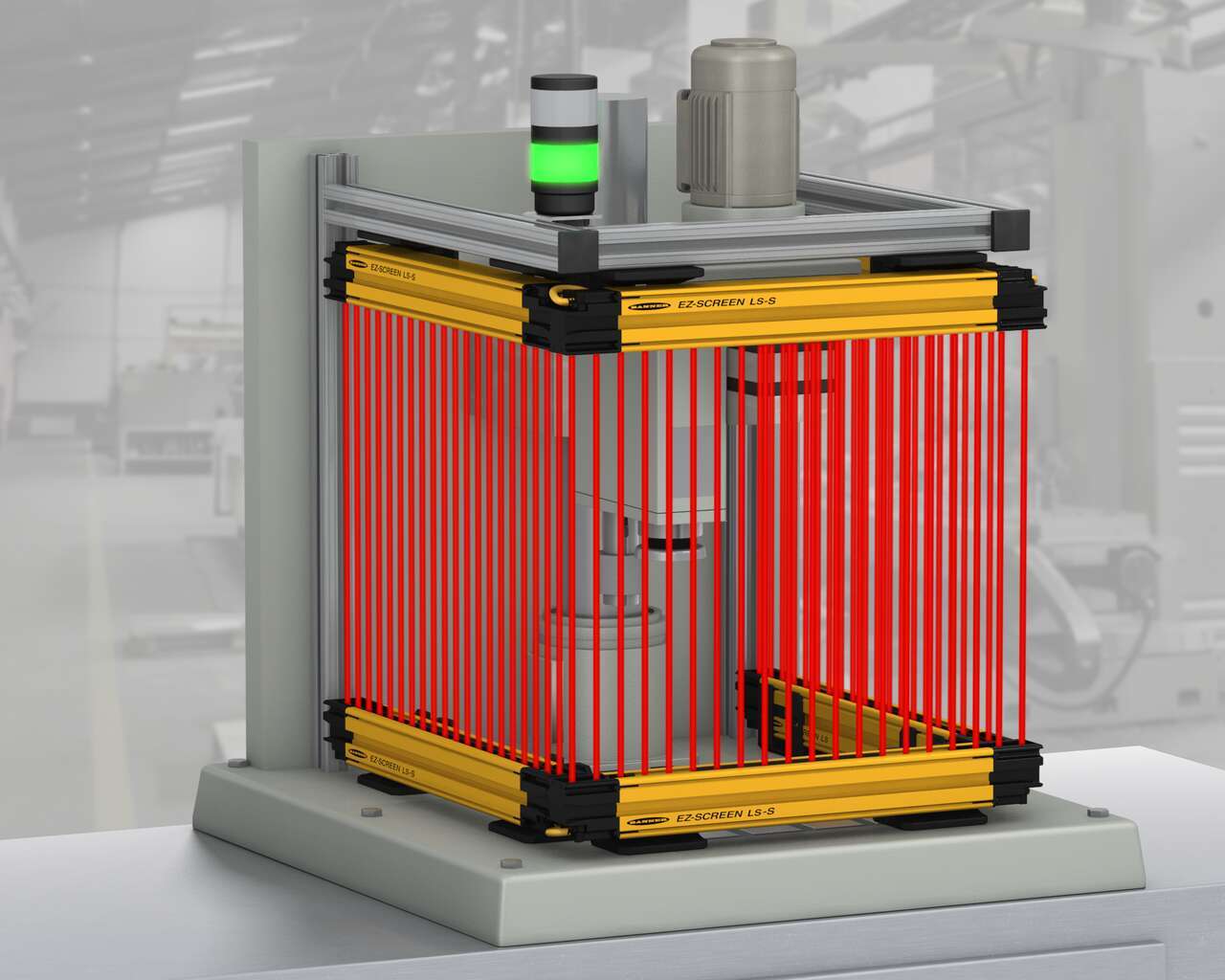

EZ-SCREEN® LS tubular enclosure light curtains are intuitive, easy-to-use safety devices used for machine safeguarding. They are built to withstand harsh environments typically found in food, beverage and pharmaceutical manufacturing.

Barriere ottiche di sicurezza serie LS Tipo 4 con custodia tubolare

Applications

Le barriere ottiche EZ-SCREEN LS non fanno uso di DIP switch, offrono funzionalità di rilevamento end-to-end e sono facili da installare grazie alla configurazione automatica. L'utilizzo di staffe di fissaggio laterali consente di velocizzare e semplificare l'installazione, con regolazioni effettuate sul lato anteriore della barriera EZ-SCREEN LS. Massimizzando i tempi di operatività e riducendo le spese per riparazioni e sostituzioni le aziende riescono a restare competitive con minor sforzo.

Le barriere ottiche di sicurezza installate su una macchina affettatrice proteggono gli operatori dalle lame affilate durante l'uso. Le condizioni ambientali sono aggressive a causa della frequente esposizione ad agenti chimici durante il lavaggio. La custodia igienica del modello EZ-SCREEN LS mantiene il personale al sicuro e previene la penetrazione di acqua e sostanze chimiche nel dispositivo.

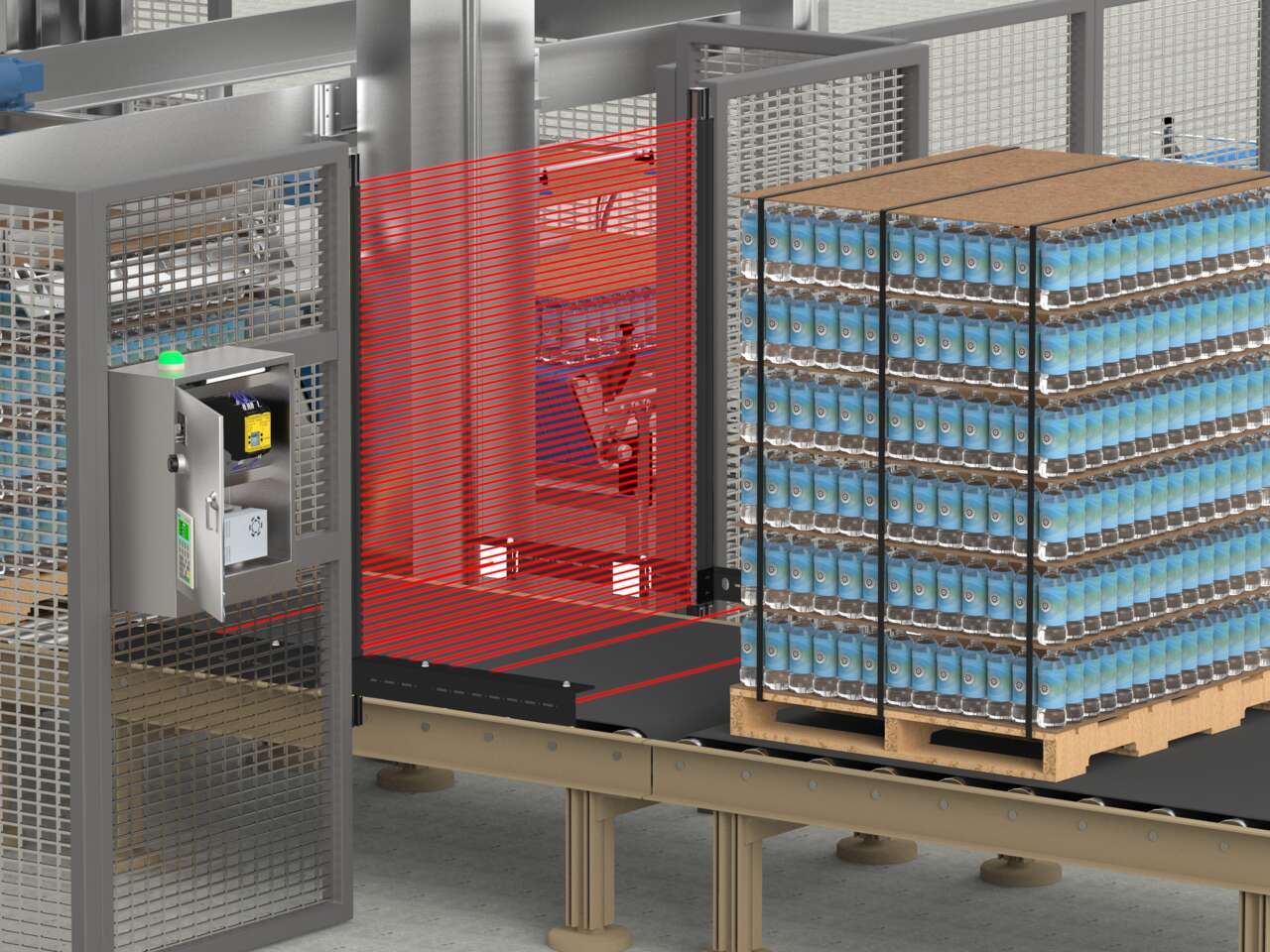

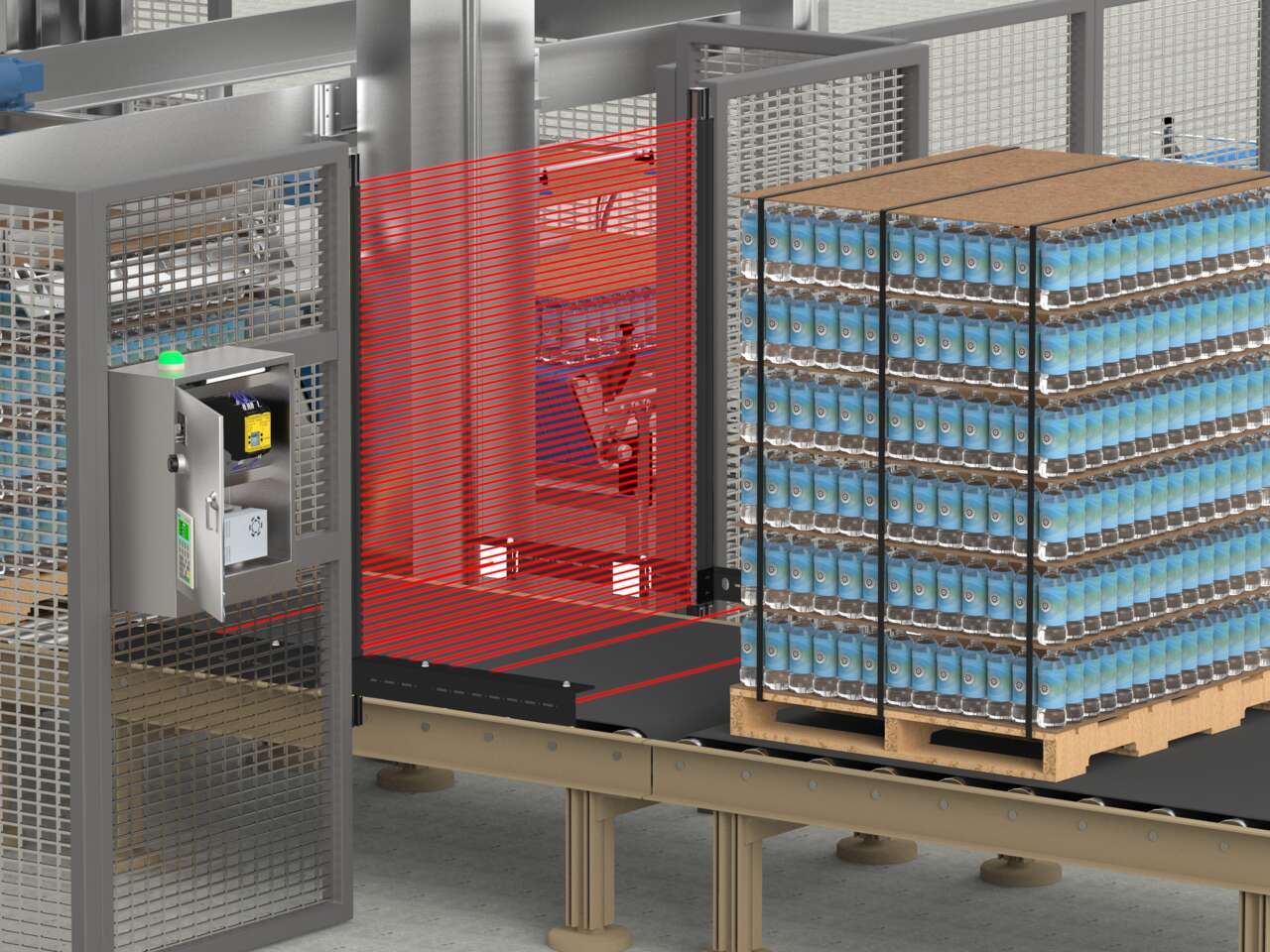

Una barriera ottica di sicurezza LS con kit supporto di muting in configurazione a "T", utilizzata in combinazione con un modulo di sicurezza Serie XS26, rappresenta una soluzione facile da implementare che protegge il personale da potenziali pericoli, senza interferire con il flusso di pallet verso il depallettizzatore.

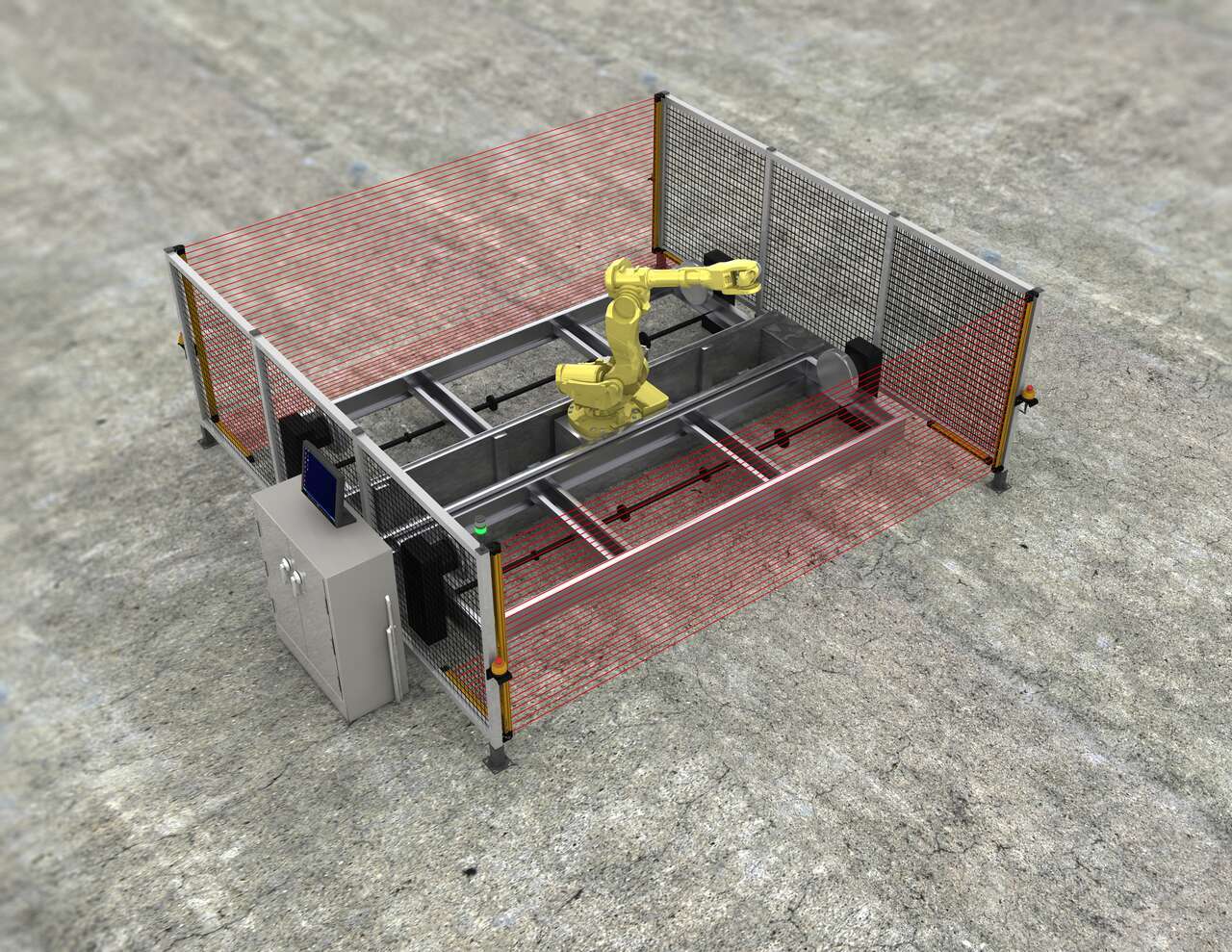

La barriera LS EZ-SCREEN di Banner è estremamente robusta e provvista di custodia in alluminio estruso heavy-duty, con grado di protezione IP65/67, teste in metallo e una finestra incassata per proteggere il sensore da eventuali urti dovuti all'asportazione del prodotto o incidenti. Oltre a ciò, la portata di 12 metri consente di proteggere presse di grandi dimensioni, superando il degrado ottico dovuto all'accumulo sulla finestra di contaminanti quali gli oli e la polvere che normalmente si depositano sulla macchina, riducendo le prestazioni del sistema.

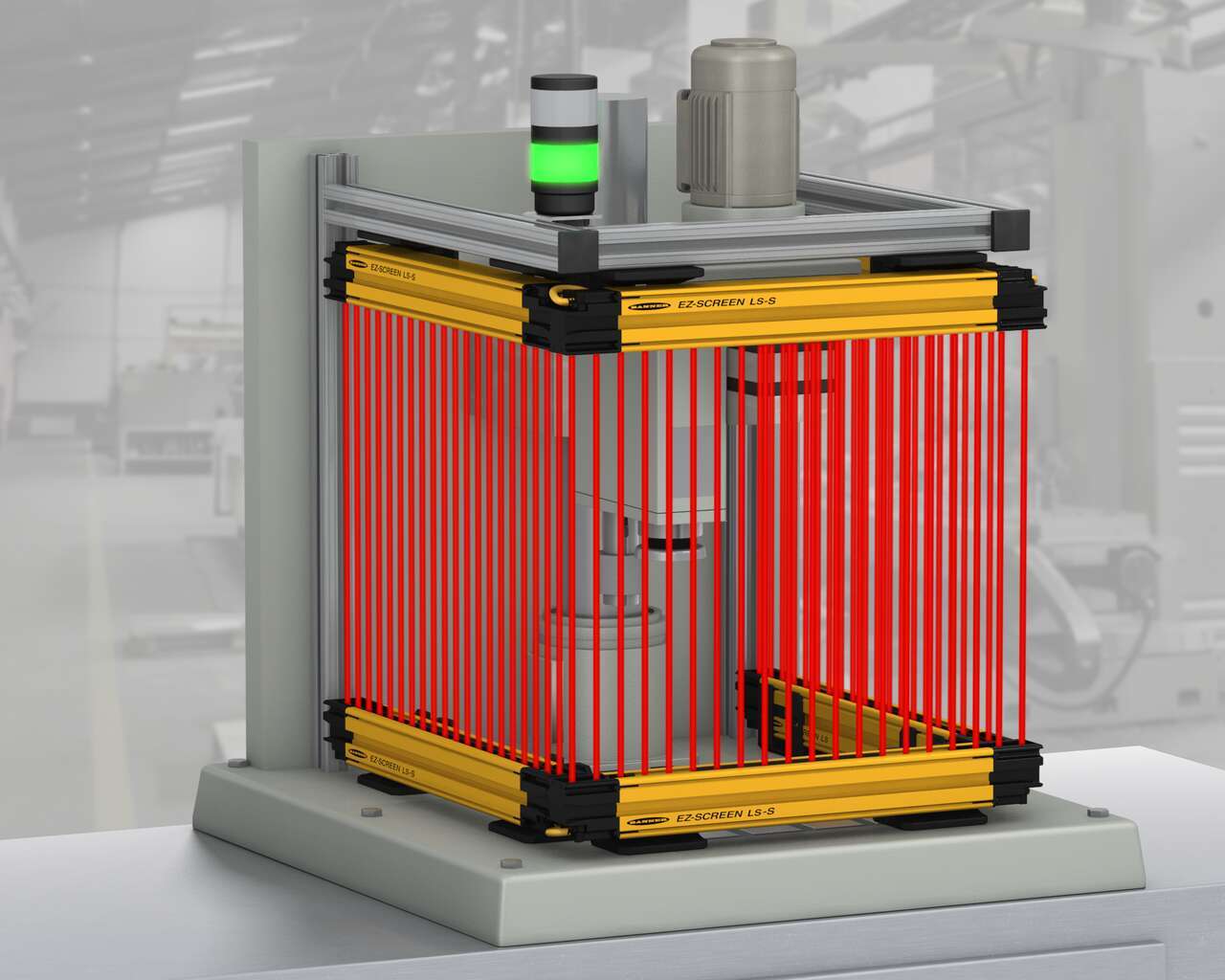

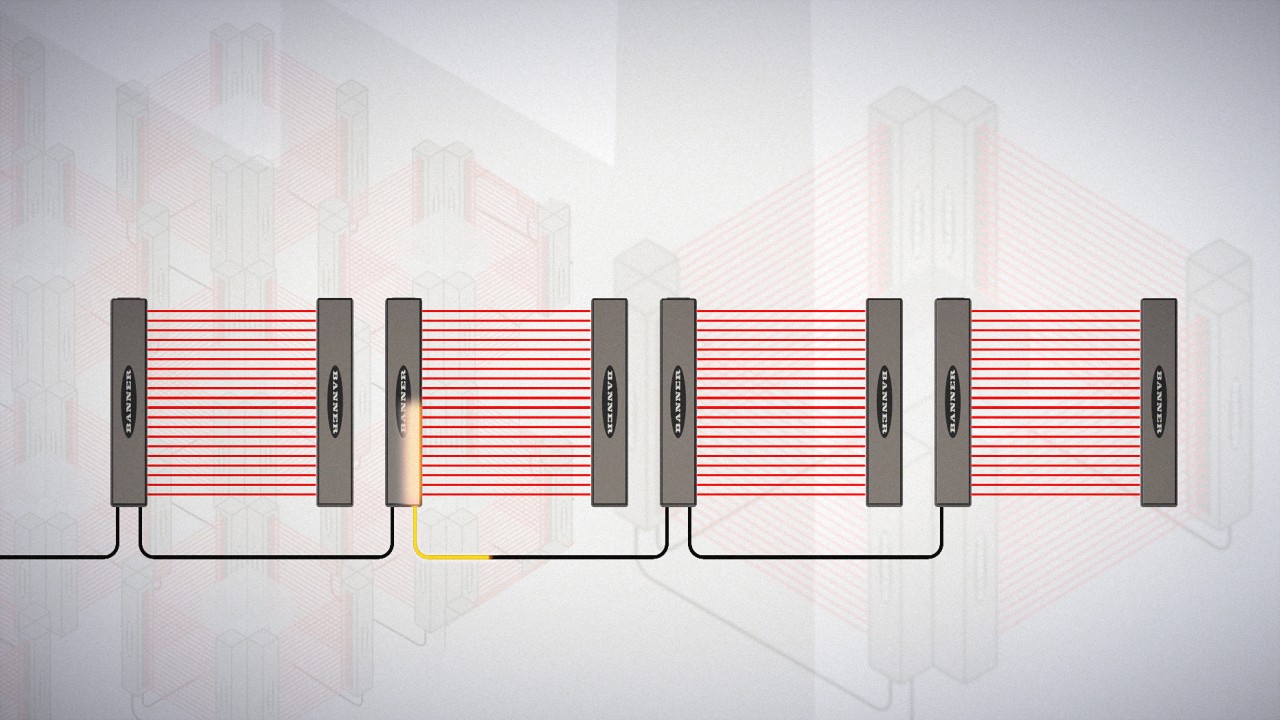

EZ-SCREEN LS di Banner Engineering offre una valida risposta a esigenze di protezione di più punti di accesso alla zona pericolosa, con funzioni automatizzate di collegamento in cascata. Questa funzione avanzata permette la connessione in serie di un massimo di quattro coppie di barriere, di qualsiasi dimensione e con qualsiasi risoluzione, utilizzando un singolo cavo per il collegamento al quadro di comando e una singola interfaccia di sicurezza a due canali, riducendo così il numero dei pannelli e quindi lo spazio occupato.

Le barriere ottiche EZ-SCREEN LS non fanno uso di DIP switch, offrono funzionalità di rilevamento end-to-end e sono facili da installare grazie alla configurazione automatica. L'utilizzo di staffe di fissaggio laterali consente di velocizzare e semplificare l'installazione, con regolazioni effettuate sul lato anteriore della barriera EZ-SCREEN LS. Massimizzando i tempi di operatività e riducendo le spese per riparazioni e sostituzioni le aziende riescono a restare competitive con minor sforzo.

Le barriere ottiche di sicurezza installate su una macchina affettatrice proteggono gli operatori dalle lame affilate durante l'uso. Le condizioni ambientali sono aggressive a causa della frequente esposizione ad agenti chimici durante il lavaggio. La custodia igienica del modello EZ-SCREEN LS mantiene il personale al sicuro e previene la penetrazione di acqua e sostanze chimiche nel dispositivo.

Una barriera ottica di sicurezza LS con kit supporto di muting in configurazione a "T", utilizzata in combinazione con un modulo di sicurezza Serie XS26, rappresenta una soluzione facile da implementare che protegge il personale da potenziali pericoli, senza interferire con il flusso di pallet verso il depallettizzatore.

La barriera LS EZ-SCREEN di Banner è estremamente robusta e provvista di custodia in alluminio estruso heavy-duty, con grado di protezione IP65/67, teste in metallo e una finestra incassata per proteggere il sensore da eventuali urti dovuti all'asportazione del prodotto o incidenti. Oltre a ciò, la portata di 12 metri consente di proteggere presse di grandi dimensioni, superando il degrado ottico dovuto all'accumulo sulla finestra di contaminanti quali gli oli e la polvere che normalmente si depositano sulla macchina, riducendo le prestazioni del sistema.

EZ-SCREEN LS di Banner Engineering offre una valida risposta a esigenze di protezione di più punti di accesso alla zona pericolosa, con funzioni automatizzate di collegamento in cascata. Questa funzione avanzata permette la connessione in serie di un massimo di quattro coppie di barriere, di qualsiasi dimensione e con qualsiasi risoluzione, utilizzando un singolo cavo per il collegamento al quadro di comando e una singola interfaccia di sicurezza a due canali, riducendo così il numero dei pannelli e quindi lo spazio occupato.

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Le barriere ottiche EZ-SCREEN LS sono dispositivi di sicurezza intuitivi e facili da usare utilizzati per la protezione di macchinari. Realizzate per resistere alle condizioni tipiche degli ambienti di produzione e di confezionamento.

Learn how Banner Engineering's light curtains' cascade signals outpace the competition, and how that translates to savings in the factory.

Learn how to set-up the XS safety controller to work with a mute arm kit and LS safety light curtain. Banner’s pre-assembled mute arm kits are available in L, T and X configurations as a plug-n-play solution for end of line packaging applications.

![EZ-SCREEN® LS [Video]](/content/dam/banner-engineering/video/video-thumbnails/products/EZ-SCREEN%20LS%20Product%20Thumbnail.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

La barriera ottica di sicurezza EZ-SCREEN LS di Banner Engineering, facile da usare, è progettata per la protezione dei macchinari in l'uso negli ambienti industriali complessi tipici dei processi di produzione e confezionamento.

EZ-SCREEN LS; Receiver; 770 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 770 mm (30.3 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 1050 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 1050 mm (41.5 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 280 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 280 mm (11.0 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 490 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 490 mm (19.3 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 630 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 630 mm (24.8 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 420 mm

Resolution: 23 mm; Range: 12 m (40 ft)

Defined Area: 420 mm (16.5 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 560 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 560 mm (22.05 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Remote Fixed Blanking; 770 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 770 mm (30.3 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 840 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 840 mm (33.1 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 910 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 910 mm (35.8 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

EZ-SCREEN LS; Receiver; 980 mm

Resolution: 23 mm; Range: 8.4 m (27 ft)

Defined Area: 980 mm (38.6 in); Housing: Black

LS Custom Connector to 8-wire Flying Leads

in Hygienic Tubular Enclosure

Please note the following information is for educational purposes only and is accurate as of the time of publication. For any safety application, discuss your specific requirements with a safety expert.

The EZ-Screen LS safety light screen does not require an external controller. All of the safety reliable components to make the light screen function are integrated into the housing of the emitter and receiver.

Although an external controller is not required, the EZ-Screen LS is commonly used with one of three types of machine controls: a safety interface module, a safety controller, or a safety PLC.

If the application requires the light screen's output to be muted, consider using a safety controller like the XS26-2, SC26-2, or a muting safety interface module like the MMD-TA-11B.

To ensure the highest safety reliability, you have the option to use an EZ-Screen LS with 5-pin connectors when connecting to a module or safety controller that has on-board External Device Monitoring (EDM), like a safety controller or the smart UM-FA-9A module.

If you prefer to have the EZ-Screen LS monitor your downstream external controls, use the models with 8-pin connectors. You would also want the 8-pin connectors if you need to monitor the Fault Output or if the light screen pair may cross-talk with other light screen pairs and you need to use an alternative scan code.

Each sensor ships with two EZLSA-MBK-11 end-mount brackets. Emitters and receivers that are 980 mm and longer also include one EZLSA-MBK-12 center-mount bracket. The supplied end-mount brackets allow ±23° rotation, can be mounted with flange out or flange in, and in 90° increments. EZLSA-MBK-12 center-mount brackets allow 30° rotation in one direction and 15° in the other. Center- and side-mount brackets allow for mounting with no blind zones.

The supplied EZLSA-MBK-12 or optional EZLSA-MBK-16 side-mount bracket must be used with longer sensors if they are subject to shock or vibration. In such situations, the sensors are designed to be mounted with up to 910 mm unsupported distance (between brackets). When ordering additional brackets for vibration, remember that sensors 980 mm and longer are supplied with one EZLSA-MBK-12 center-mount bracket.

Cascadeable models can be used as stand-alone light screens or can be cascaded up to four pairs in one system. The cascaded sensor pairs can be any length, any number of beams, or have different resolutions (14 mm, 23 mm, and 40 mm), as long as each emitter matches its receiver.

A non-cascadeable pair can be used at the end of the cascaded light curtains. A cascadeable receiver is required to use a EZLSA-K30LGR light.

The tighter resolution light screens are made to detect smaller objects. In general, the 14 mm resolution screens detect fingers and larger, the 23 mm resolution screens detect hands and larger, and the 40 mm resolution screens detect wrists and larger. Larger resolution light screens need to be placed farther away from the safety hazard than smaller resolution light screens to account for the additional distance a person’s finger can possibly slip through the beams without being detected.

The calculation for the minimum safety distance based on resolution and machine response time is in section 3.1.1 of the EZ-Screen LS User Manual. The beams must be at least 100 mm (4 inches) away from the safety hazard regardless of the calculated value. You should discuss your specific application with a safety expert.

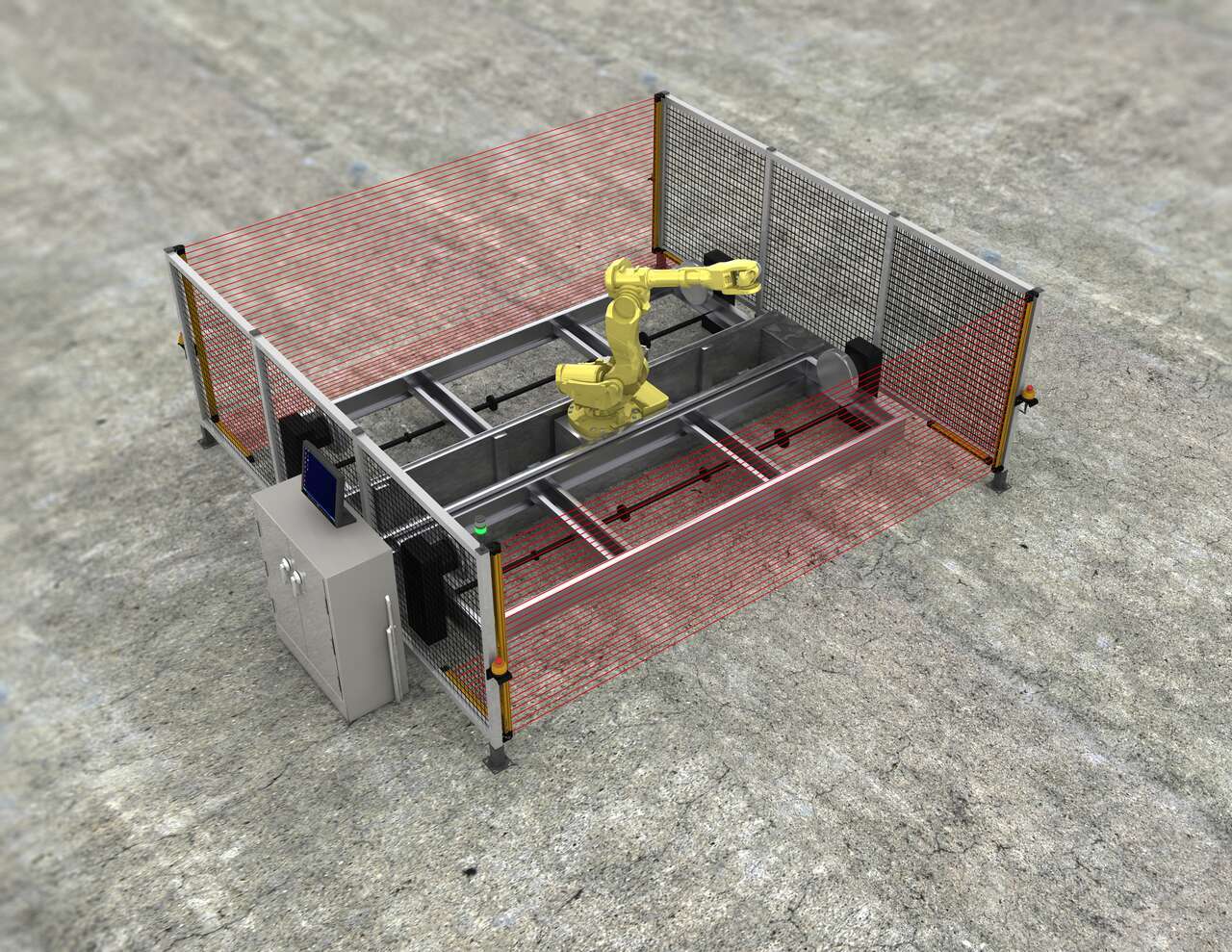

Mirrors would be used most commonly in a perimeter guarding situation when protecting multiple sides of a machine. They are generally placed at the corners of a machine.

We have two options for mirrors: the MSM series and the SSM series. The SSM mirrors are larger and so, therefore, may be easier to align. There is a reduction of range of approximately 8% per mirror and is detailed in this chart. The use of a laser alignment tool is advised when using mirrors at longer distances. Discuss your specific application with an expert.

Yes, as long as you use a cascadable model.

For any safety application, a risk assessment is essential to help you determine what safety devices are needed for compliance with safety standards. Learn more about risk assessments.

Have a question about this product series? Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.