Kitting and Sequencing

Build Kits and Assemblies Quickly and Accurately

Kitting involves assembling separate but related items into a single unit or kit that is packaged together.

In Just In Time (JIT) manufacturing, sequencing refers to delivering kits of materials to the next station exactly when they are needed to ensure maximum efficiency.

For example, in automotive manufacturing, kits of parts are delivered to the next stage of production at exactly the time that a kit is needed. Assembling kits in this way is also known as "offline kitting."

Pick-to-light solutions help ensure kits are assembled accurately at a fast pace and can be delivered to the next stage of production at the right time.

Ensuring Quality in Kit Building is Essential

Kitting and sequencing applications can be challenging because kits and other assemblies are often made of many different components. Each kit must be assembled correctly to ensure that end users, or assemblers at the next stage of production, receive a complete kit.

Due to the number of items, and the variety of kits that may be assembled at a station, it can be easy for assemblers to lose track of what has already been put in the kit. For example, they may accidentally leave out items or add duplicate items, which increases costs and makes parts inventory management a challenge.

Manually verifying that each kit is complete, and does not contain duplicates, is time-consuming and prone to error. Therefore, it is necessary a solution that can streamline assembly tasks and verify accuracy.

Just In Time sequencing applications depend on a fast, accurate kit building to ensure that kits arrive at the next station at the right time and contain all of the necessary parts.

Ensure Quality Even in Large, Complex Assemblies

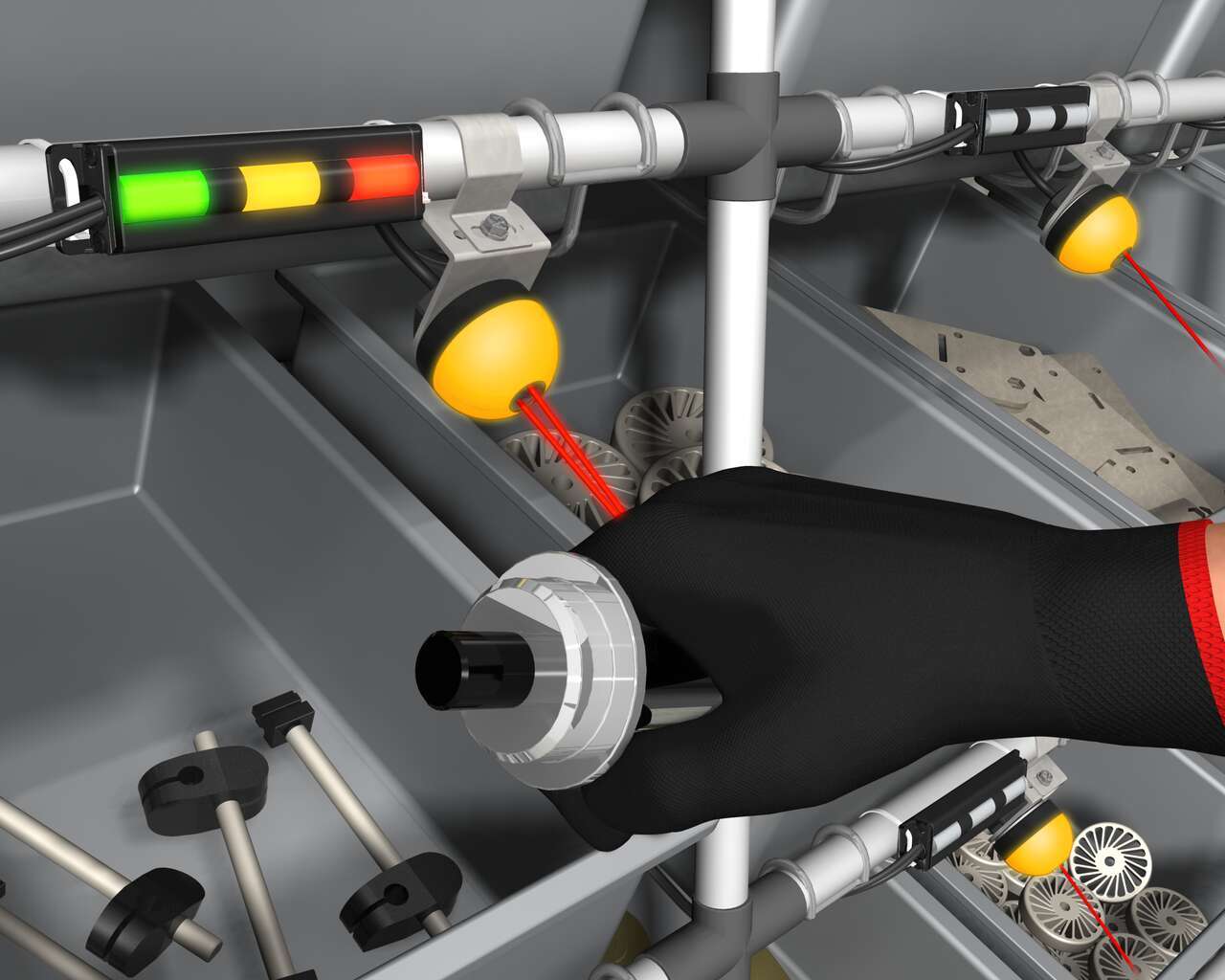

- At stations where multiple different kits are assembled, specific colors can be assigned for each kit. Pick-to-light devices illuminate with the corresponding color, such as blue, alerting the operator to pick items from all the bins with blue lights.

- Devices with an alphanumeric display indicate the quantity of each item to pick.

- After an operator has transferred the items from each pick bin to the color-matched kit bin, they press the blue touch button to signal that they are finished, and the light turns off.

- The process is repeated with additional colors, and once all the lights are off, that round of kit is complete.

Check Pick Accuracy in Real Time

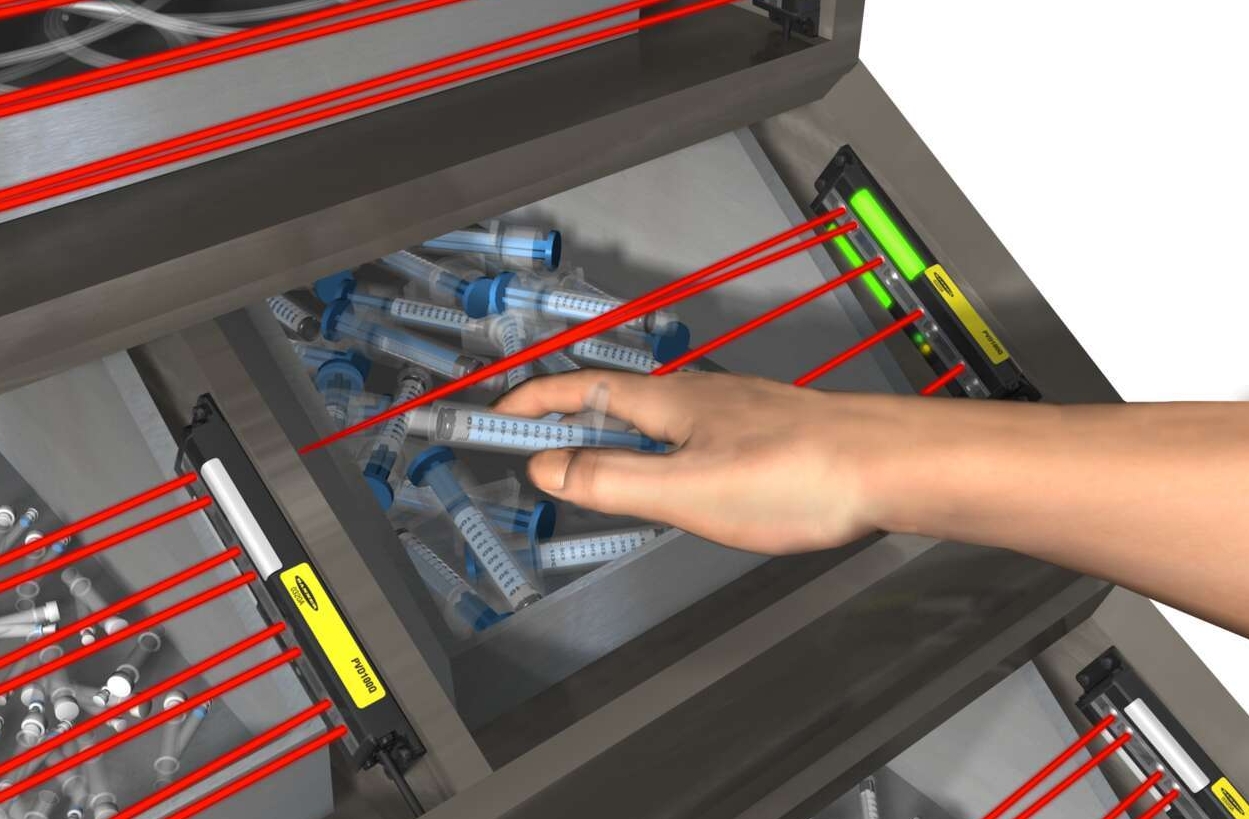

- Pick-to-light devices with optical sensing capabilities can be used to check picks for accuracy in real time.

- These devices detect when a hand reaches into a bin and breaks the sensing beam or array.

- When picks are executed correctly, yellow LEDs confirm that the operator picked from the right bin.

- If the operator reaches into the wrong bin (for example, to pick the wrong item or pick a piece out of order), a light turns red indicating an error.

Reduce Wasted Time and Save Costs

- Light-guided solutions speed up onboarding time for new employees, as well as training on new product assembly. Different colors of lights are easy to interpret quickly with minimal training.

- Pick-to-light solutions reduce time wasted re-reading instructions, as well as checking and re-checking work.

- By verifying parts at each step, pick-to-light solutions can reduce errors during the assembly process and save time during quality inspections downstream.

- Improving efficiency at both assembly and inspection stages reduces overhead costs and increases profitability.

Pick-to-Light Devices

Die Bauform K50 Pro Touch ist eine vielseitige Bauform. Sie verbindet eine große, helle Anzeige mit einer Transistorschalterfunktion, die durch einfache Berührung betätigt werden kann. Ideal für Lean Manufacturing und Bestückungsvorgänge. Die K50 Pro-Taster verbinden eine bewährte Touch-Technologie und Robustheit mit zusätzlicher Vielseitigkeit durch RGB-LEDs. K50 Pro Touch-Taster sind mit der Pro Editor-Software kompatibel und lassen sich leicht anpassen

- Helle LED-Anzeigen in Kombination mit berührungsaktivierten Schaltfunktionen

- Kompatible Modelle sind mit der Pro Editor-Software und dem Pro Converter-Kabel von Banner programmierbar, um Farben und Animationen anzupassen.

- Robuste IP67- und IP69K-Konstruktion für Umgebungen mit hohem Spritzdruck

- Ergonomisches Design erfordert keinen physischen Druck zum Bedienen und entlastet die Hände und Handgelenke

- Ideal für Bestückungsvorgänge und Ruftasten-Anwendungen in einer Vielzahl von Branchen und Umgebungen – von Lebensmitteln und Getränken bis zur Automobilindustrie

- Bis zu vierzehn Farbvariationen in einem Gerät (Grün, Rot, Gelb, Blau, Weiß, Cyan, Magenta, Orange, Gelb, Limonengrün, Frühlingsgrün, Himmelblau, Violett und Rosa)

- IO-Link-Modelle verfügen über volle Pro-Funktionen, die dynamisch vom Master verwaltet werden, sowie eine individuelle LED-Steuerung für eine vollständige Statusanpassung

Pick to Light Devices

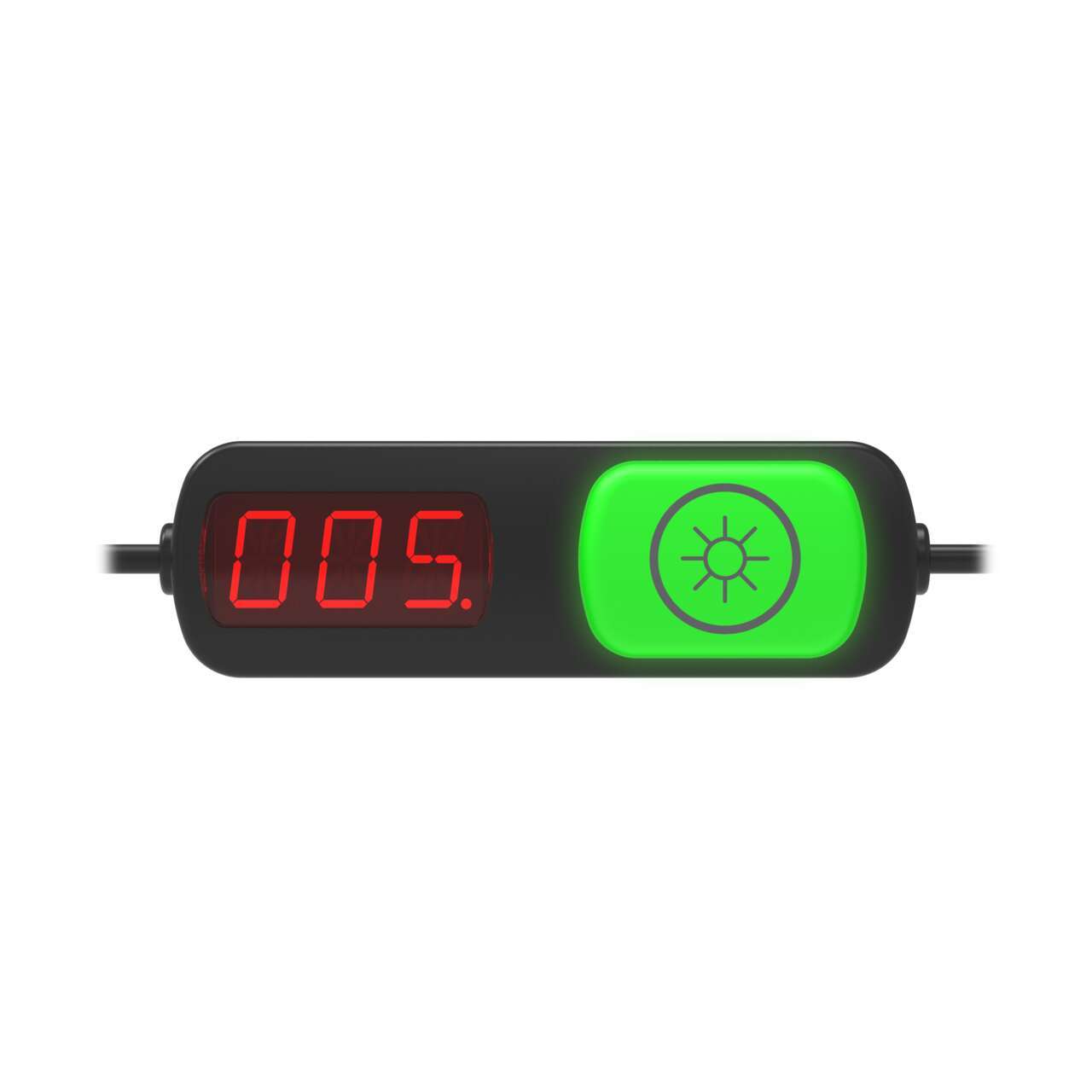

Eine kleinere Ausführung der Bauform K50 ist die Bauform K30 Bestückung. Diese verbindet eine helle Kontrolllampe mit einer Transistorschalterfunktion mit Berührungsaktivierung.

- Ergonomisches Design: Betrieb ohne physischen Druck, was Hände und Handgelenke schont

- Einfache Betätigung durch Berührung mit einem Finger

- Einfache Betätigung mit unbedeckten Händen oder Arbeitshandschuhen

- Robuste, vollvergossene IP69K-Konstruktion für Umgebungen mit hohem Spritzdruck

- Ideal für Bestückungs- (Pick-to-Light) und Ruftastervorgänge in diversen Branchen

- Ein- und zweifarbige Ausführungen erhältlich für diverse Anwendungen