Factory Communication and Process Optimization

Communicate Better, Improve Worker Productivity

Industrial Internet of Things (IIoT) technologies are not just useful for optimizing machines. In fact, wireless technologies enable seamless interaction among human workers as well, and can have a significant impact on the efficiency of manual or semi-automated production and assembly lines.

Keep reading to learn how IIoT technologies enable better communication throughout the factory and streamline processes for machines and people alike.

Combining wireless communication with bright indication enables more seamless interaction between machines, workers, mobile equipment, and their managers throughout the factory.

Workers can quickly and easily interpret signals from LED indicators with clear, bright local displays, especially when each status is represented by a unique color or animation.

Furthermore, LED indicators with wireless communication make it easy to quickly send and receive these signals from anywhere in the factory--and respond in a timely manner.

Keep Stations Stocked for Continuous Workflow

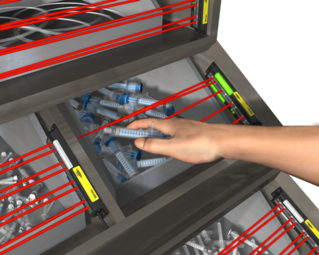

Assembly workers need the correct supplies in order to build products and maintain a smooth workflow. Restocking assembly stations on-time, before components run out without overstocking and creating congestion at a station can be a challenge. Real-time communication between assemblers and the forklift operators who stock their stations enables a more efficient delivery of components as well as the timely removal of completed products.

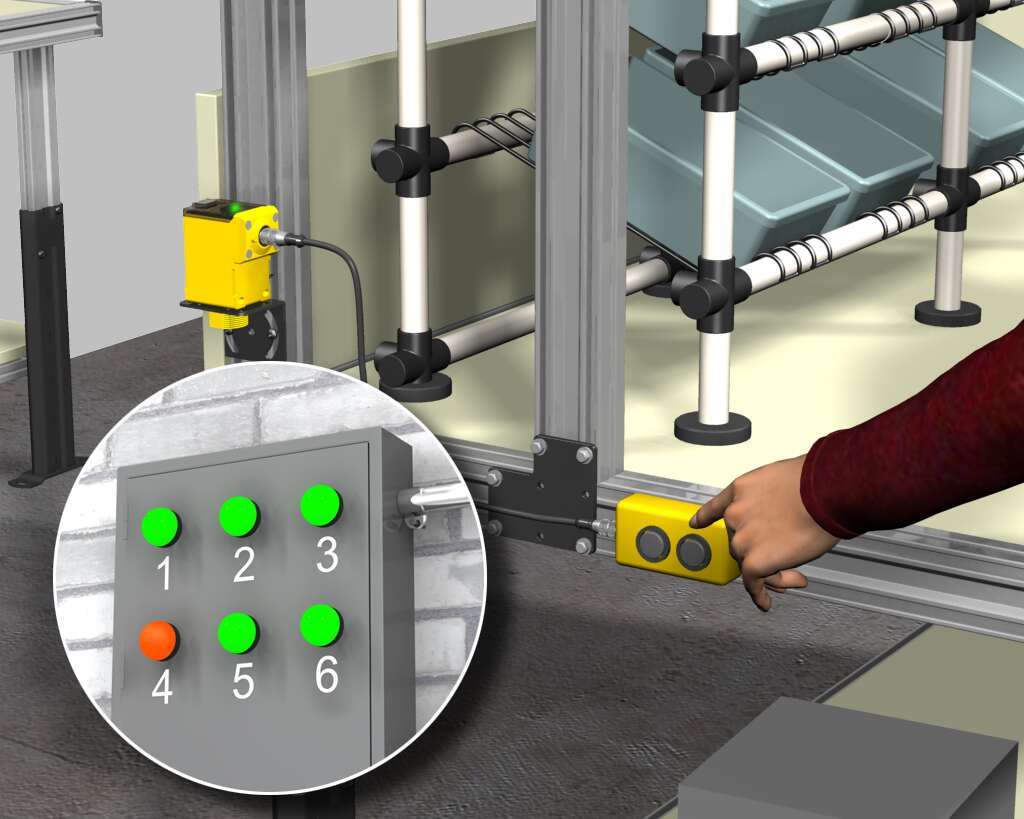

When an assembly station needs to be restocked, a worker can simply touch a button at their station. The button sends a signal to a pendant that the forklift operator carries. A red LED light on the pendant that corresponds with the assembly station will begin to flash, notifying the forklift operator where parts are needed. The driver can quickly acknowldege the request by pushing a button on the pendant, letting the operator know more material is on the way.

Use Data to Identify Process Improvements

A wireless call-for-parts, service, or pallet pickup system increases efficiency by allowing up to 18 work stations to call out to six forklifts or Hi-Los. A wireless solution enables quicker responses from forklift drivers and/or supervisors to indicate a request has been accepted. When creating a call system using wireless indicators, work stations can maintain a steady workflow and resolve critical issues quickly.

A wireless solution can also track total time to fulfill requests, number of requests, and time to acknowledge requests. This allows managers to analyze average delivery and acknowledgement times for each station and make process improvements as needed.

Reduce Time Spent Checking In Unnecessarily

Instead of requiring machine operators to walk over to the manager area for assistance with a technical issue, a wireless system utilizing connected pushbuttons or switches and tower lights can be used to alert managers when assistance is needed on the line.

For example, a notification system might be set up so that an operator pushes a button or flips a switch to alert the manager or technician that he or she is needed on the production line. Wireless pushbuttons equipped with LED status lights can also facilitate 2-way communication by configuring the LED to change color when the manager or technician indicates that he or she is on their way.

Using a wireless notification system reduces the need for technicians and managers to constantly check each production line and for workers to leave their workstations when they need assistance. By streamlining communications, managers, technicians, and line workers are able to use their time more productively.

Wireless Pushbuttons and Switches

Sure Cross® Q45-Schalter und -Drucktaster sind für den Anschluss an externe potentialfreie Kontakte, NAMUR und diskrete kontaktlose Schaltereingänge geeignet und lassen sich vielseitig in der Fabrikautomation, der Fernüberwachung und IIoT-Anwendungen einsetzen.

- Für die Fernüberwachung geeignete Ausführungen lassen sich an Eingänge mit isolierten potentialfreien Kontakten oder an induktive NAMUR-Nähesensoren anschließen.

- Ausführungen mit Taster und Lampe haben unabhängig gesteuerte Drucktastereingänge und eine mehrfarbige LED-Kontrolllampe.

- Für die Fernüberwachung geeignete Ausführungen mit kontaktlosem Schalter verwenden einen Reed-Schalter und einen Magneten, um die Position mechanischer Vorrichtungen wie Türen, Hebeln, Ventilen und anderen Auslösern zu erfassen.

Wireless Button and Light Pendant

Das Sure Cross® Q120 Funktaster- und Anzeigegerät ist ein autonomer Funkknoten, der die Zweiwege-Kommunikation zwischen einem Bediener und bis zu sechs externen und/oder Mobilgeräten ermöglicht.

- Sechs unabhängig gesteuerte Drucktastereingänge ermöglichen es den Bedienern, per Funk Statusaktualisierungen und Quittierungen zu senden, Prozesse zu initiieren und Geräte auszulösen.

- Sechs rote und grüne LED-Anzeigen bieten eine lokale Anzeige der Status von externen oder Mobilgeräten und Maschinen.

- DIP-Schaltereinstellung

Wireless LED Touch Button

Der 70-mm-Funktaster der Bauform K70 ist ein großer, einfach zu aktivierender Festkörperschalter und eine gut sichtbare Anzeige. Taster dieser Bauform eignen sich perfekt für Bestückungs-, Ruftaster- und allgemeine Industrieanwendungen.

- Exzellente Unempfindlichkeit gegen falsche Auslösung durch Spritzwasser, Reinigungsmittel, Öle und andere Fremdmaterialien

- Ergonomisch geformt; keine Hand-, Gelenk- und Armbelastung bei wiederholter Schalterbetätigung; kein körperlicher Kraftaufwand zur Betätigung erforderlich

- Einfache Betätigung mit unbedeckten Händen oder Arbeitshandschuhen

- Verfügbar in neun Farboptionen und ein-, zwei- und dreifarbigen Ausführungen

- Betrieb bei 12 bis 30 V DC