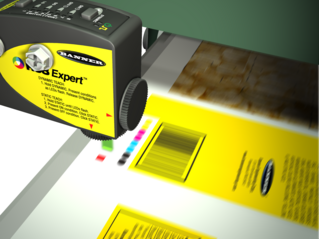

Multicolored Targets and Product Changeover

Multicolored targets are increasingly becoming the norm, especially in consumer packaged goods industries. The various types of packaging used include shiny, glossy, or other unpredictable surfaces.

For example, reflective, multicolored, and wrinkled material such as foil or film is frequently used in food and beverage packaging and can cause inconsistent sensor readings.

Multicolored targets are challenging for many sensors to consistently detect. This is because some colors, such as very dark colors, are more difficult for traditional photoelectric sensors to see because darker colors reflect back less light back to the sensor compared to lighter colors. Multicolored targets also have frequent color transitions and varying amounts of reflectivity that further impact sensing reliability.

Product changeover creates additional challenges because sensors must be able to reliably detect a variety of color combinations. To keep up with consumer demand, manufacturers require flexible sensing solutions that can detect all colors and that can be quickly updated with each new "recipe" during product changeover to keep production lines moving.

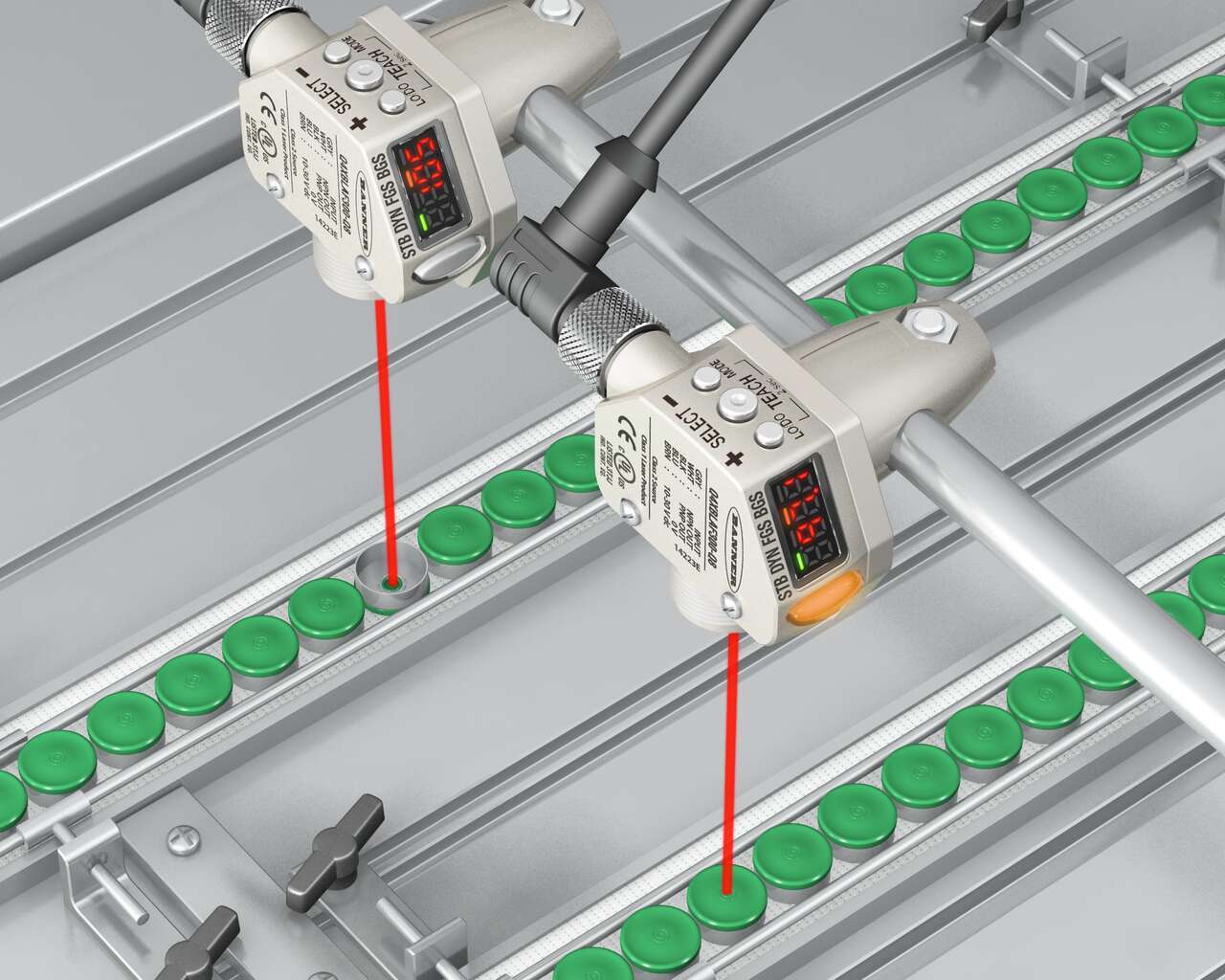

Laser distance sensors are an excellent choice for detecting multicolored packaging because cause they determine target presence or absence using distance. Laser distance sensors are unaffected by color transitions, and they can reliably detect all different varieties of packaging, regardless of color or reflectivity.

In addition, many laser distance sensors from Banner Engineering feature exceptionally high excess gain to reliably detect very dark colors, as well as automatic gain adjustment to dynamically increase or decrease sensing power depending on target reflectivity.

With IO-Link, users can easily read and change device parameters through the control system software, enabling fast configuration and commissioning that saves time and resources.

In addition, IO-Link sensors can accommodate multiple recipes that can be quickly and dynamically changed from the control system as needed—such as in the case of product changeover. For example, a line that runs products of different sizes at different times will require changes to sensors’ distance thresholds.

Manufacturers use many terms to describe sensor performance, but not all manufacturers use the same specifications, which can make it challenging to compare different models of sensors. Read the article to learn tips for choosing the right sensor for any application.

Laser Distance Sensor with IO-Link, 25-610 mm

Vielseitige, robuste Laser-Abstandssensoren bieten eine herausragende Leistung und können Entfernungsveränderungen von Bruchteilen von Millimetern erfassen.

- Ausführungen mit Schaltausgang, Analogausgang (0 bis 10 V oder 4 bis 20 mA), zur Erfassung transparenter Objekte und mit IO-Link erhältlich

- Zuverlässige Erfassungsreichweite von 25 mm bis 610 mm

- Erfassung von Zielen in diversen Farben, Materialien und Oberflächen anhand der Entfernung

- Doppelter Programmiermodus (Intensität und Entfernung) eignet sich ideal für Fehlerprüfungsanwendungen und ermöglicht die Erfassung transparenter Objekte ohne Reflektor

- Robustes Gehäuse der Schutzart IP69K aus Edelstahl in FDA-Güte

Laser Distance Sensor with IO-Link, 9.5 cm to 2 m

Der Q5X Lasersensor mit Hintergrundausblendung ist ein leistungsstarker Sensor zur Problemlösung in einem kostengünstigen Gerät mit rechteckigem Gehäuse nach Industriestandard.

- Reichweite von 9,5 cm (4") bis 2 m (6 ft. 6")

- Dank seiner außergewöhnlich hohen Funktionsreserve erfasst der Sensor zuverlässig besonders dunkle Objekte (schwarze Reflektoren

- Erfasst zuverlässig schwarze Objekte vor schwarzem Hintergrund, schwarze Objekte vor glänzendem Metallhintergrund, durchsichtige und reflektierende Objekte, mehrfarbige Verpackungen und Objekte aller Farben.

- Der duale Teach-Modus misst sowohl den Abstand als auch die Lichtstärke und bewältigt dadurch schwierigste Anwendungen.